How to Select a Laser Marking System

When selecting a laser marking system for a particular application there are many factors to consider:

power density

time

reflectivity

material

wavelength

temperature

thermal

thermal conductivity

heat capacity

melting point

heat of vaporisation

Power density is determined by the amount of (peak) power generated by the laser pided by the area of focused beam. Wavelength, beam pergence and optics quality become important factors in determining how small a focus spot can be produced.

The length of time the laser is focused on one spot also affects the ease of marking and depth of penetration. Sometimes, the pulse duration is a key factor in determining which laser can be used.

Reflectivity or absorptivity is determined by the material, surface condition (i.e. smooth or rough, polish or oxidised), wavelength of the laser beam and surface temperature. In general, metals absorb a greater percentage of Nd:YAG laser energy than that of carbon dioxide laser energy. White paper and most transparent materials absorb a great amount of carbon dioxide laser energy. Some materials such as silicon absorb the same percentage of energy from either laser.

To evaluate available laser marking systems in the market for the application, the following factors should be focused on:

laser specifications

optical delivery systems

control system and software

ease of operation

manufacturer's performance record

price

Each type of laser has its own set of specifications. For CW lasers, the major specifications are:

wavelength

beam quality factors (beam spot size, M2, pergence angle, or beam parameter product)

power stability

average laser power

Q-switch element performance (maximum pulse repetition rate, minimum pulse duration, laser peak power)

For pulsed lasers, the specifications are:

wavelength

average laser power

maximum peak power

maximum energy per pulse

pulse repetition rate

pulse duration

pulse-to-pulse stability

beam quality factors (beam spot size, M2, pergence angle, or beam parameter product).

There are many types of optical delivery systems. A mask marking system may include a beam expander, homogeniser, CCD camera and monitor or/and microscope, and projection lens. The projection lens and the diameter of the beam incident on it determine the size of image focused on the object surface. This focus size and output laser energy/peak power also determine the energy/power density on the work piece. For beam deflected marking system, the system may include beam expander, CCD camera and monitor or/and microscope, scanner, fiber optics, and flat field scanning (f-q) lens. The f-q lens is very important in determining focused spot size, marking field, minimum marked-line width and power density on the work piece. The scanner together with the marking software determines the scanning speed.

Control systems and software are very different for different laser marking systems. The control system may include feeding of work piece, stage, control of beam on/off, and interfaces among computer, laser generator, stage, and protection/alarm systems. The laser marking software also include facilities for controlling other external devices such as work handlers and transport mechanisms as well as interfaces to external triggers for "marking on the fly" applications. The marking software should be easy to implement in a system and to program conveniently. It should be compatible to commercially available software in the market. The marking software must generate the required drive and control signals for not only the motion and speed of the marking head but also the laser power (via D/A card).

Relevant references:

Beam expander

Basics of f-theta lens

Optics for laser scanners

Basics of 2-axis laser scanner (marking system

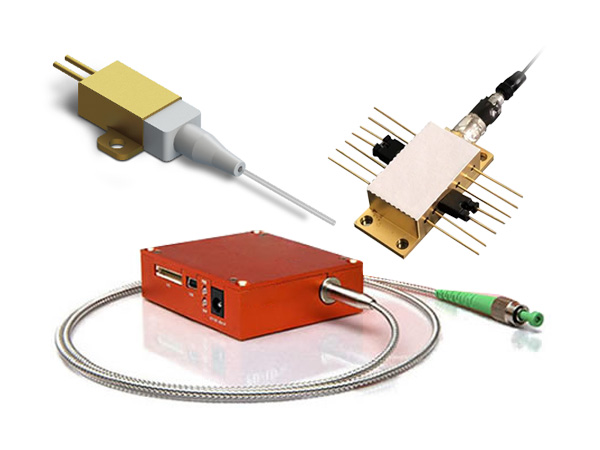

Mini fiber laser marker

DPSS laser marker

English

English Français

Français Deutsch

Deutsch euskara

euskara Русский язык

Русский язык Italiano

Italiano Português

Português Nederlands

Nederlands Polski

Polski Greek

Greek Lietuva

Lietuva Türkçe

Türkçe 日本語

日本語 한어

한어 中文

中文 தாமில்

தாமில் فارسی

فارسی हिंदी

हिंदी Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Pilipino

Pilipino Indonesia

Indonesia தாமில்

தாமில்