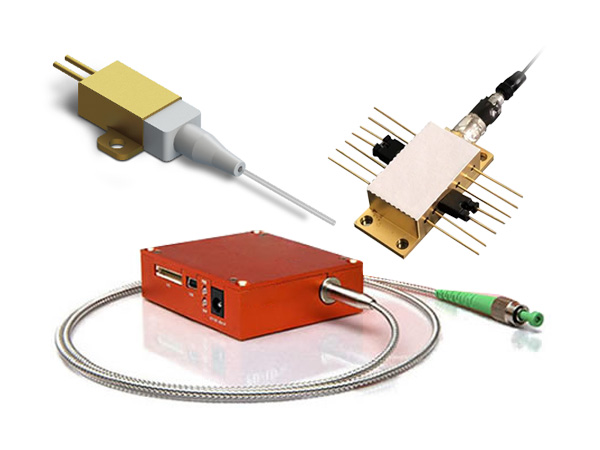

Ultrafast Laser 3D Manufacturing System

Our proprietary technology on advanced ultrafast lasers based 3D manufacturing (Additive Manufacturing and Subtractive Manufacturing) opens a variety of opportunities in many fast-growing industries like aerospace, defense, bio-medicals, sensors, and communications.

The unique competitive advantages of the technology provide us with the capability of developing laser 3D manufacturing products, which are maintenance-free and cost-effective for both industrial and scientific applications.

3D Laser Manufacturing

3D printing/additive manufacturing has attracted significant attention over the last decade and it can create complex parts that are difficult to be manufactured traditionally. Compared with conventional laser AM techniques (thermally melted welding), the fs fiber laser AM offers many advantages including localized high temperature heating, manipulating microstructures and macrostructures, uniform mixing of dissimilar materials, limited HAZ, and stable sub-micron grain structure. It is the ideal solution for 3D manufacturing of high temperature materials and fine structures. Moreover, subtractive manufacturing (SM) can be naturally integrated to make hybrid (AM and SM) process by using fs fiber laser.

Nonlinear Imaging and Microscopy

Our femtosecond fiber lasers provide vital tools for nonlinear biomedical imaging such as multi-photon imaging (MPI) and Coherent Anti-Stoke Raman Spectroscopic (CARS) microscopy. Our supercontinuum fiber lasers provide a wide bandwidth (over 2000 nm) enabling Optical Coherent Tomography (OCT) and wavelength tuneable microscopy.

For more information, please contact us at sales@sintec.sg

English

English Français

Français Deutsch

Deutsch euskara

euskara Русский язык

Русский язык Italiano

Italiano Português

Português Nederlands

Nederlands Polski

Polski Greek

Greek Lietuva

Lietuva Türkçe

Türkçe 日本語

日本語 한어

한어 中文

中文 தாமில்

தாமில் فارسی

فارسی हिंदी

हिंदी Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Pilipino

Pilipino Indonesia

Indonesia தாமில்

தாமில்