Principle of Acousto-Optical Q-switch

The acousto-optical Q-switch often used in the laser marking makes use of mutual interaction between an ultrasonic wave and a light beam in a scattering medium. The light beam that enters in a direction forming a Bragg angle to the wave surface of the acoustic wave in the scattering medium is diffracted in accordance with periodic changes in the diffraction rate produced by the acoustic wave.

The situation is briefly explained in Figure 1. First of all, an RF signal is impressed to the transducer adhered to the molten quartz and thickness extensional vibration is produced. Ultrasonic shear waves are caused to advance in the molten quartz by this vibration, and phase grating formed by acoustic waves is produced. The laser beam is diffracted when it satisfies the Bragg angle with respect to this phase grating, and is separated in space from the incident light.

Figure 1: Principle of A-O Q-switch

If the laser optical resonator is constructed against 0-dimensional diffracted light (undiffracted light), the diffracted light deviates from the laser optical resonator axis when a RF signal is impressed. As a result, loss occurs in the laser optical resonator and laser oscillation is suppressed. To make use of this phenomenon, an RF signal is impressed for a certain length of time only (status of low Q-value) to suspend laser oscillation. In the meantime, the population inversion of the Nd:YAG rod is accumulated by continuous pumping. When the RF signal is reduced to zero (status of high Q-value) and the loss to the laser optical resonator is removed, the accumulated energy is activated as laser oscillation in a pulse form within an extremely short length of time. They are Q-switch pulses.

This situation is briefly explained in Figure 2. When an RF signal is subjected to pulse modulation, it is possible to periodically take out a Q-switch pulse. When the period of Q-switch pulses becomes shorter than the life (about 200 s) of the higher order of the Nd:YAG rod, however, the population inversion decreases and the peak value of Q-switch pulses decreases.

Figure 2: Laser oscillation output of a Q-switch laser

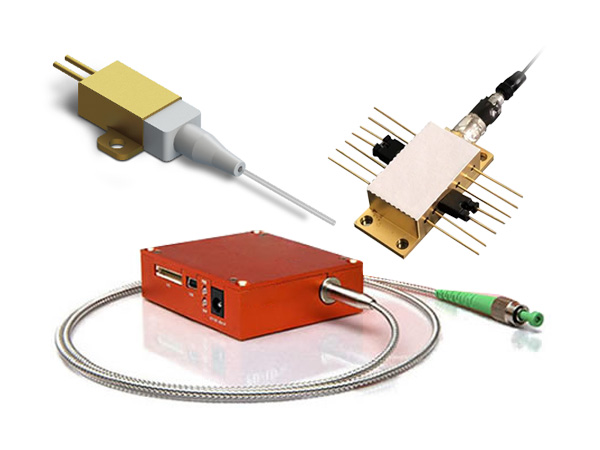

The following pictures show the relations among the main laser parameters such as average power, peak power, pulse width, pulse energy and diode current (proportional to diode laser’s power). The data comes from a diode end pumped Q-switched laser.

Frequently Asked Questions

1. Which parameters do I need to specify if I want to order a Q-Switch?

You will need to specify the frequency, aperture, acoustic mode and the type of water connector.

2. Which frequency should I use?

The answer depends on your location. There are various regulatory bodies (for example the ITU) that stipulate the maximum levels of RF radiation that can be emitted in certain frequency bands. The Q-Switch drive frequency is usually chosen to be within one of the permitted bands for the country in which it will operate. Historically, 24.0MHz has been the chosen frequency in the USA and Japan and 27.12MHz in Europe and elsewhere. However, this has been less rigidly observed in recent years and 27.12MHz is now used widely in the USA.

3. What is the difference between clear aperture and active aperture? ,

The clear aperture of a Q-Switch is defined by the size of the block of silica in which the light and sound interact. For the QS24/27 Series the minimum clear aperture is 9mm.

The active aperture is defined by the height of the acoustic beam inside the silica block. This is the dimension that matters when specifying a Q-Switch.

4. How do I select the appropriate aperture for my application?

As a rule of thumb, the active aperture of the Q-Switch should be the same as the beam diameter of the laser at the point where the Q-Switch will be located. If the gain of the laser is modest it may be possible to use a Q-Switch with an active aperture one size smaller than the actual beam diameter (e.g. a 3mm active aperture Q-Switch in a laser with a 4mm diameter rod). This has the advantage of requiring lower RF drive power (drive power scales linearly with active aperture), which means less heat input and consequently greater efficiency and improved beam quality. It may even mean a lower cost driver can be used. On the downside, alignment of the Q-Switch in the cavity may be more critical.

5. Which acoustic mode would suit me best?

The choice is between shear (S) mode and compressional (C) mode (also known as longitudinal mode). If your laser is unpolarised you should choose shear mode. For polarised systems better results (less RF power = lower cost driver, less heat = better beam quality) will be obtained by using a compressional mode Q-Switch.

6. Which water connector should I choose?

The choice is between screw-on (S) connectors with a nut and olives which grip the outside of the flexible tubing, and barbed (B) push-on connectors, which grip the inside of the flexible tubing. There is little to choose between the two and it usually depends what type of pipe fitting is used as standard in the laser system. Overall the push-on fittings are probably best because there is no danger of them restricting the water flow. (The olives in the screw-on type can constrict the soft-wall tubing usually used in laser systems.)

7. How do I know that the Q-Switch is not over-heating?

The Q-Switch is fitted with a thermal interlock. If, for example, the cooling water fails it will shut down the driver when the temperature reaches 50 degrees C, preventing damage to the Q-Switch.

8. What is the optimum operating temperature of the Q-Switch?

The temperature should be set slightly above ambient to prevent the possibility of condensation forming on the optical surfaces of the Q-Switch. Around 32 degrees C is typical. For optimum performance and lifetime we do not recommend operating the Q-Switch at temperatures above 40 degrees C.

9. How do I know that the QS24/27 Series Q-Switch is the best choice for my application?

Please call one of our engineers if you are in any doubt about which Q-Switch to use. The QS24/27 Series Q-Switches are 'industry standard' devices that have been developed and refined over many years. As a result they are very reliable and because they are manufactured in large quantities they are lower cost than some of the more specialised products we can offer. Basically, if you have a lamp-pumped industrial or medical Nd:YAG laser this is probably the Q-Switch for you. It is also suitable for the latest generation of high-power industrial diode-pumped lasers.

10. I am designing a compact laser and the QS24/27 Series Q-Switch is too large. What should I do?

G&H manufacture a range of standard compact Q-Switches that may be suitable for your application. If not, we have considerable experience of designing application-specific Q-Switches. We supply Q-switches to many of the leading diode-pumped laser manufacturers and it is likely that we will have a design that can easily be adapted to suit your requirements.

11. I have a single-mode polarised laser. Will the QS24/27 Series Q-Switch be suitable? ,

Yes. You can use a compressional mode version with a small active aperture (3mm or less). However, you may find that the integrated Q-switch, with its integral RF driver is a more cost effective solution that also offers performance advantages in terms of higher average Q-Switched output power.

12. How much laser power can I hold off? ,

It depends on the design of your laser cavity, where the Q-Switch is placed in it and so on. Hold-off is not a parameter of the Q-Switch alone, but of the Q-Switch/laser combination. We can however determine the extra-cavity loss modulation of the Q-Switch, which is a direct measure of its effectiveness at blocking the laser beam.

13. I have a high gain laser and need the maximum possible loss modulation. How do I achieve this? ,

There are two ways; by using two compressional mode Q-Switches in series and orientated such that the acoustic beams are orthogonal to each other you can obtain a high, polarisation insensitive, loss modulation with minimum RF drive power. Also available is a newly developed Q-Switch incorporating two orthogonal compressional mode transducers in a single monolithic cell and mounted in one convenient housing. A dual channel RF driver is available for both applications.

14. Can I trust the damage threshold quoted in the data sheet?

Yes. We periodically send a sample Q-Switch to a NIST certified test house to have the optical damage threshold verified. G&H take the utmost care in the polishing of the optical surfaces and in their preparation and coating. All these operations are carried out in-house in order to have total control of the process.

For more information on Q-switches, please go there.

English

English Français

Français Deutsch

Deutsch euskara

euskara Русский язык

Русский язык Italiano

Italiano Português

Português Nederlands

Nederlands Polski

Polski Greek

Greek Lietuva

Lietuva Türkçe

Türkçe 日本語

日本語 한어

한어 中文

中文 தாமில்

தாமில் فارسی

فارسی हिंदी

हिंदी Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Pilipino

Pilipino Indonesia

Indonesia தாமில்

தாமில்