Review of Laser Processing Technology

**Abstract:**

Laser technology has revolutionized various industries, offering precise, efficient, and versatile solutions for marking, cutting, welding, and cleaning applications. This paper provides a comprehensive review of the latest advancements, trends, and applications in the laser industry, focusing on laser marking, cutting, welding and cleaning processes. We delve into the principles behind each process, highlighting recent technological innovations, emerging trends, and their impact on industrial sectors.

**Keywords:** Laser technology, laser marking, laser cutting, laser welding, laser cleaning, industrial applications, technological advancements.

1. Introduction

The advent of laser technology has transformed manufacturing processes across multiple industries, offering unprecedented precision, speed, and efficiency. Laser-based techniques such as marking, cutting, welding, and cleaning have become indispensable tools in modern manufacturing, enabling intricate designs, superior quality, and cost-effective production. This review explores the evolution of laser technology and its diverse applications in industrial settings.

2. Laser Marking

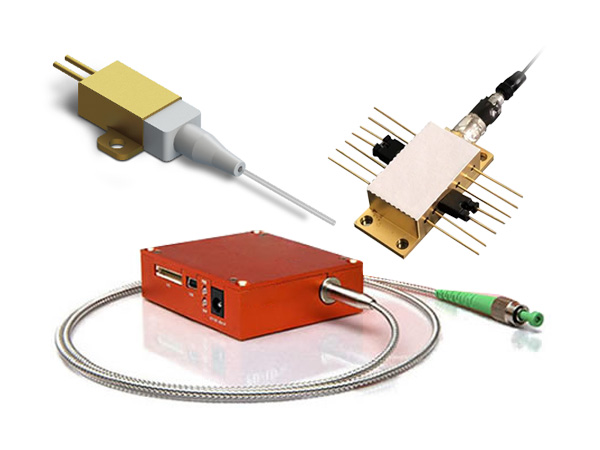

Laser marking, also known as laser engraving, involves the use of lasers to create permanent marks on various materials. This section discusses the principles of laser marking, including different techniques such as engraving, annealing, and foaming. We examine advancements in laser sources, including fiber lasers, CO2 lasers, and diode lasers, as well as innovations in marking software and automation technologies. Applications in automotive, aerospace, electronics, and medical industries are highlighted, showcasing the versatility and precision of laser marking solutions.

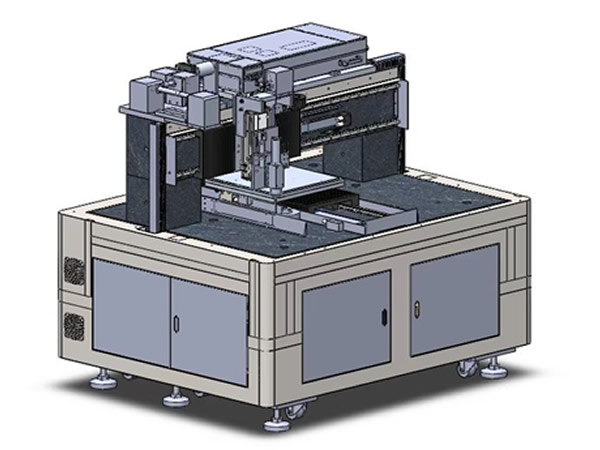

3. Laser Cutting

Laser cutting has emerged as a preferred method for precision machining of various materials, including metals, plastics, ceramics, and composites. This section explores the fundamentals of laser cutting processes, including CO2 laser, fiber laser, and Nd:YAG laser technologies. Recent developments in beam delivery systems, control mechanisms, and cutting strategies are discussed, along with applications in sheet metal fabrication, automotive manufacturing, electronics, and signage industries. The advantages of laser cutting, such as high accuracy, speed, and flexibility, are emphasized.

4. Laser Welding

Laser welding offers distinct advantages over traditional welding methods, including reduced heat-affected zones, minimal distortion, and precise control over welding parameters. This section examines the principles of laser welding, encompassing techniques such as conduction welding, keyhole welding, and hybrid welding. Advances in laser sources, optics, and process monitoring systems are explored, along with applications in automotive assembly, aerospace components, medical devices, and electronics manufacturing. The potential for laser welding to enhance productivity, quality, and sustainability in welding operations is discussed.

5. Laser Cleaning

Laser cleaning has emerged as an environmentally friendly alternative to traditional cleaning methods, utilizing lasers to remove contaminants, coatings, and residues from surfaces without the use of chemicals or abrasives. This section elucidates the principles of laser cleaning, including techniques such as ablation, surface modification, and paint removal. Recent developments in laser sources, beam delivery systems, and control algorithms are examined, along with applications in automotive maintenance, historic preservation, aerospace refurbishment, and industrial cleaning processes. The benefits of laser cleaning in terms of efficiency, safety, and environmental sustainability are underscored.

6. Future Perspectives and Challenges

The paper concludes with an outlook on the future of laser technology, including anticipated advancements, emerging applications, and challenges to be addressed. Topics such as additive manufacturing, ultrafast laser processing, and quantum technologies are identified as areas of active research and development. The importance of interdisciplinary collaboration, standardization, and workforce training is emphasized to fully harness the potential of laser technology in addressing evolving industrial needs.

7. Conclusion

In summary, laser technology continues to drive innovation and transformation across diverse industries, offering unparalleled capabilities for marking, cutting, welding, and cleaning applications. By staying abreast of the latest advancements and embracing emerging trends, manufacturers can leverage laser technology to enhance productivity, quality, and sustainability in their operations.

English

English Français

Français Deutsch

Deutsch euskara

euskara Русский язык

Русский язык Italiano

Italiano Português

Português Nederlands

Nederlands Polski

Polski Greek

Greek Lietuva

Lietuva Türkçe

Türkçe 日本語

日本語 한어

한어 中文

中文 தாமில்

தாமில் فارسی

فارسی हिंदी

हिंदी Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Pilipino

Pilipino Indonesia

Indonesia தாமில்

தாமில்