Laser Welding Technology in the Application of Aluminum Alloy Products

In recent years, aluminum alloy laser welding technology has developed rapidly, greatly promoting the wide application of aluminum alloy. The technology combines the advantages of two heat sources and overcomes their respective shortcomings, becoming a new type of welding method that is receiving more and more attention.

Aluminum alloy, as a common raw material for industrial products, has an important role in reducing the weight of the body and preventing corrosion, especially in the automobile manufacturing industry is widely used, such as engines, wheels and instrument panels. Processing methods include welding and cutting. The high performance of laser welding machines not only enhances processing efficiency, but also provides excellent welding results, helping to improve the industry's process level. The following are the advantages of laser welding in aluminum alloy products.

Aluminum alloy laser welding machine uses pulsed or continuous laser beam to directly irradiate the surface of aluminum alloy, the laser heat quickly spreads to the inside of the aluminum alloy, forming a weld, and at the same time generates a reaction force, which makes the surface of the melted aluminum alloy concave to form a small hole.

The advantages of laser welding machine in the application of aluminum alloy products include:

1. high energy density, low heat input, small thermal deformation, narrow melting zone and heat-affected zone, and large melting depth.

2. High cooling rate, fine weld organization, excellent joint performance.

3. Compared with traditional welding, laser welding does not use electrodes, reducing labor and costs.

4. Can weld metal materials inside closed transparent objects.

5. The laser can be transmitted remotely via optical fiber, with good process adaptability. With the cooperation of computer and robot, the welding process can be automated and precisely controlled.

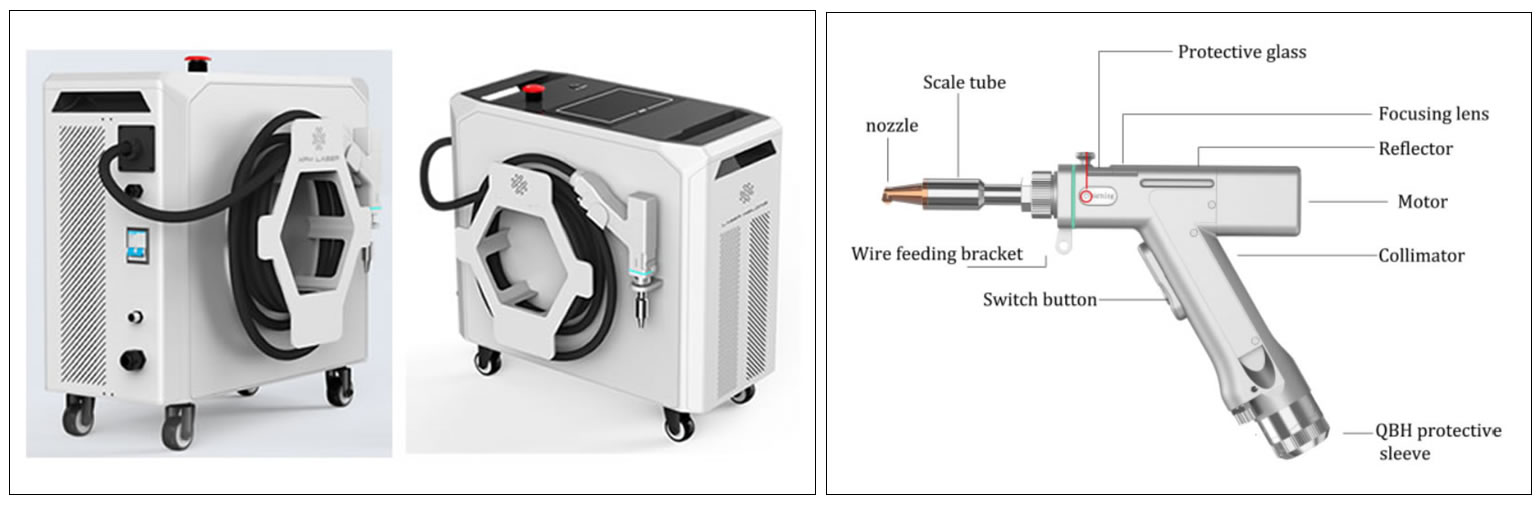

With the popularization of laser processing applications, laser welding machine in aluminum alloy product welding is increasingly used, small heat input, heat source concentration. In particular, the introduction of fiber laser welding machine, further enhance the energy density and focus of laser welding. The forming effect and quality of aluminum alloy welding can be significantly improved by laser wire filling, laser MIG hybrid welding and dual-point laser welding technology.

The handheld laser welding machine can be widely used in cabinet kitchen and bathroom, stairs and elevators, shelves, ovens, stainless steel doors, windows and guardrails, distribution boxes and other industries, and can efficiently complete the complex and irregular welding process. Stainless steel, aluminum, copper and other materials can be welded, suitable for a variety of hardware devices, such as triangular valve, stainless steel sinks, water pipe fittings, stainless steel round pipe tee pipe, floor drains, door handles and door locks.

For more information on laser welding products, please click here.

English

English Français

Français Deutsch

Deutsch euskara

euskara Русский язык

Русский язык Italiano

Italiano Português

Português Nederlands

Nederlands Polski

Polski Greek

Greek Lietuva

Lietuva Türkçe

Türkçe 日本語

日本語 한어

한어 中文

中文 தாமில்

தாமில் فارسی

فارسی हिंदी

हिंदी Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Pilipino

Pilipino Indonesia

Indonesia தாமில்

தாமில்