3 Minutes to Understand Microchip Lasers

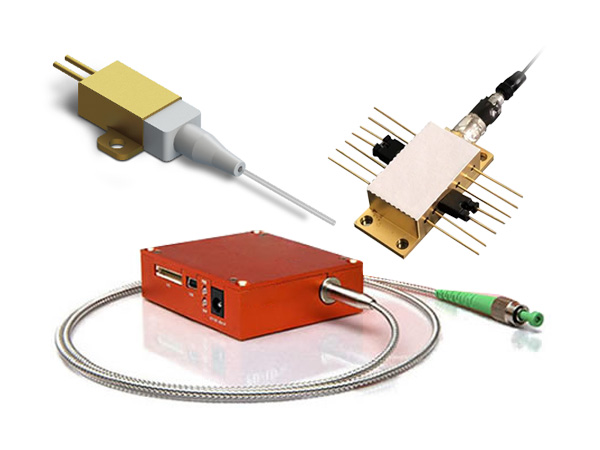

Microchip laser is a laser diode-pumped, small, all-solid-state pulsed laser with a highly doped crystalline material as the gain medium, and the cavity length is generally controlled on the order of millimeters. As the cavity length is relatively short, it greatly shortens the photon life in the resonant cavity, which is easier to achieve the laser's short pulse width output, and good beam quality, high laser brightness, can also be realized in a single longitudinal mode single frequency laser output. It is also due to this feature, making this type of laser structure is very compact, long life, easy to mass production.

At present, the world's definition of microchip lasers is not particularly clear, the usual sense is that microchip lasers are a passive Q-modulated, sub-nanosecond, high peak power micro solid-state lasers. However, this definition usually refers to microchip lasers in which the gain medium is Nd:YAG, Nd:YVO4, which is not comprehensive. For example, for passively Q-tuned micro solid-state lasers with Er glass, the definition of sub-nanosecond is not very accurate since the pulse width is usually around 5ns. In addition, with the laser manufacturing level of iterative upgrading, more and more compact and miniaturized active Q-switched narrow pulse width miniature solid-state lasers will be available, the definition of microchip lasers is believed to be rewritten. Microchip lasers have high cost-effective, miniaturized structure and are widely used in laser ranging, LIDAR, laser processing, laser seed source, biomedical, laser induction, Raman spectroscopy detection, mass spectrometry and scientific research.

1. Structure and characteristics of microchip laser

Gain medium for Nd: YAG, Nd: YVO4, passive Q crystal using Nd: Cr4 + YAG microchip laser, the output wavelength of 1064nm, 532nm can be achieved by frequency doubling, combined frequency or quadruple-frequency can also be achieved for the 355nm and 266nm laser output, the pulse width of the more common 1ns near the 700ps, 500ps, etc., the shortest pulse width can be achieved for the domestic At present, the shortest pulse width of 300ps can be realized. This kind of laser, pulse width between picoseconds and nanoseconds, has a very strong peak power, and at the same time can ensure a relatively short pulse width. Compared with nanosecond lasers, they can make up for the thermal effects of nanosecond lasers due to wider pulse widths. For example, in the medical cosmetology industry, the skin will produce thermal effect under the action of nanosecond lasers, and improper operation will easily cause skin damage, while sub-nanosecond lasers will produce mechanical effect in human skin to achieve the therapeutic goal without damaging the skin at the same time. Another example, in the field of material micromachining, nanosecond lasers with wide pulse widths cause thermal buildup of the material, thus making the processing effect unsatisfactory, while sub-nanosecond microchip lasers can precisely make up for this deficiency. Compared with the picosecond or femtosecond laser, this kind of microchip laser although the pulse width and their comparison is not narrow enough, but hundred picoseconds pulse width can still be applied in most fields, in addition, microchip laser due to the compact structure, cost-effective and high stability, easier to batch production and other characteristics, in the industrial field of application is more broad.

2. 1535nm passively Q-switched human eye-safe microchip lasers

Gain medium for Er glass microchip laser, the output wavelength of 1535nm, can be widely used in human eye safety ranging. At present, we can realize 200-300μJ energy output, 10-20Hz repetition frequency and pulse width of 5ns around. This kind of laser is usually very high stability, can be used in -40 ℃ ~ 60 ℃ temperature environment.

3. Active Q-switched narrow pulse width lasers

Active Q-switched narrow pulse width laser is not the traditional sense of the microchip laser, but its size has been made smaller and smaller, the pulse width is also made more and more narrow. We have done the pulse energy of 250μJ, heavy frequency up to 5kHz, pulse width as narrow as 2ns active Q-switched lasers, the size and microchip laser size is similar. Compared with passive Q sub-nanosecond microchip lasers, active Q-switched narrow pulse width lasers, in addition to higher pulse energy and pulse frequency, its time jitter can be less than 1ns, much lower than microchip lasers microseconds, to meet some of the requirements of the time jitter is very high for the application areas, such as fluorescence life testing.

4. Main applications of microchip lasers

Microchip lasers are very suitable for high-volume industrialized applications due to their compact structure, high stability and superior cost performance.

1) Ranging Application

There is a wide range of lasers for distance measurement, and all laser types, including semiconductor lasers, all-solid-state lasers, fiber lasers, etc., have a wide range of applications in the field of distance measurement.

The advantages of microchip lasers in ranging applications are: small size, light weight, wide temperature operating range, and high peak power. These indicators, resulting in microchip lasers can be in the extreme use of the environment, as the most critical components of the transmission system, integrated in a very compact device, and can detect a relatively long distance. Currently, laser rangefinders are moving towards the trend of high safety, long measuring distances, high accuracy, low power consumption and miniaturization. The emission laser of the previous generation of rangefinders is not a safe laser for the human eye, and it is easy to damage the human retina, which is very unfavorable for use. Miniaturization, high reliability of 1535nm in the rangefinder is more and more widely used, the full popularity will be an inevitable trend.

In recent years, the demand for Er glass-based 1535nm human eye safety laser is increasing day by day. Especially in the military field, due to the requirements of the temperature range is extremely harsh (generally in the -40 ℃ ~ 60 ℃), and the requirements of a very small and light package, resulting in the domestic 1535nm microchip laser indicators are gradually better than similar foreign products. Currently known domestic 1535nm human eye safety ranging laser products, single pulse energy of 200μJ, repetition frequency of 10Hz, pulse width of 5ns laser components, its weight has been achieved within 10g, the length of 25mm; and for a single pulse energy of 300μJ detection of a longer distance laser, the weight of 12g or less, the length of 35mm. data. The data show that the domestic 1535nm human eye safety laser has easily passed the -40℃~60℃ extreme temperature start-up test, and the index is better than similar foreign products. In addition, for the 1535nm human eye safety ranging laser with high heavy frequency requirement above 1 kHz, the domestic level also achieves the single pulse energy output above 40μJ. Miniaturized human eye safety laser distance measuring machine is mainly composed of four parts: laser transmitter module, optical transceiver system, laser receiving system and signal processing system. The human eye safety ranging system adopts Er glass solid-state laser to generate 1535nm laser with several hundred microjoules energy, low heavy frequency and narrow pulse width, adopts InGaAs APD as signal detection, and TDC for time-of-flight measurement, so as to obtain accurate distance information.

2) Three-dimensional imaging radar application

Three-dimensional laser radar is different from single-point laser ranging radar, in addition to detecting the presence and distance of the target, but also through the scanning system or surface array imaging system, to solve the problem of detecting what and how the target is. Laser imaging radar has a wide application market in many fields such as geological and agricultural and forestry feature capture, military target identification and tracking, architectural design planning, resource exploration, security and search and rescue, etc. The application of this technology has filled every corner of modern civilization. The current active Q narrow pulse width laser, passive Q sub-nanosecond laser components and systems are very suitable for this field.

Typical single-point LIDAR transmits laser signals collimated by an optical system, irradiates the measurement target, collects the reflected and scattered light signals from the target through an optical receiving system, and analyzes and acquires the various information of the returned signals through a photodetector and a signal processing system. In order to capture the multi-point distance information on the target, the subsequent successive development of three-dimensional scanning LIDAR in the imaging surface, three-dimensional imaging LIDAR based on surface array detector technology. Distance selective technology is the use of pulsed laser and selective camera shutter cooperation, so that the radiation pulse reflected back by the measured target scene just in the camera selective opening time to reach the camera and imaging, which can greatly reduce the impact of backward scattered light, improve the system's detection sensitivity and recognition of the distance, this technology has been widely used in the three-dimensional imaging LiDAR.

3) Micromachining Applications

Unlike high-power fiber lasers and all-solid-state lasers, microchip lasers are more suitable for micromachining of hard and brittle materials. Currently, micromachining systems are trending toward smaller size, lighter weight, and more precise processing performance. Traditional hard and brittle materials processing laser used for nanosecond lasers, pulse width is generally more than 5ns, huge volume, high environmental requirements, poor stability, and thermal effect is larger, for many materials processing effect is not ideal. In addition, picosecond, femtosecond lasers in micromachining performance, although better, but expensive, bulky. High-power, high-frequency sub-nanosecond lasers are a class of cost-effective quasi-ultrafast lasers, both picosecond laser processing accuracy and ordinary nanosecond laser price advantage, in the field of precision micromachining has a broad application prospects, doubly favored by industrial customers.

The micromachining system for hard and brittle materials usually consists of pulsed laser, CCD camera, laser collimation and focusing and imaging optical system, galvanometer control system or multi-dimensional moving and rotating platform, input/output control module, computer and control software. Utilizing the high-energy characteristics of laser, it realizes marking, punching, scribing, cutting, internal carving and other processing of materials through the interaction between photons and materials. Because of its advantages of high efficiency, high precision and non-contact, it is widely used in microelectronics, micro-mechanics and micro-optical processing and other fields.

5. Summary and Outlook

In addition to the above applications, microchip lasers are also widely used in meteorological radar, Raman detection, laser ultrasound, laser-induced fluorescence, laser-induced breakdown spectroscopy, time-flight mass spectrometry, and medical cosmetology. With the continuous upgrading of microchip laser technology, in addition to the common wavelengths: 1535nm, 1064nm, 532nm, 355nm, 266nm, more special wavelengths such as 1030nm, 976nm, 946nm, 860nm, 800nm, 515nm, 488nm, 473nm, 430nm, 400nm, 343nm, 257nm, 400nm, 473nm, 430nm, 400nm, 343nm, 257nm, 237nm, 213nm, etc. have also been or will be added. In addition, for sub-nanosecond microchip lasers, the repetition frequency and single pulse energy will be further optimized. For 1535nm eye-safe microchip lasers, the single-pulse energy will be further improved to meet the requirements of eye-safe ranging at longer distances while maintaining a sufficiently compact and stable package structure.

For more information about microchip lasers, passive Q sub-nanosecond lasers, please click here.

English

English Français

Français Deutsch

Deutsch euskara

euskara Русский язык

Русский язык Italiano

Italiano Português

Português Nederlands

Nederlands Polski

Polski Greek

Greek Lietuva

Lietuva Türkçe

Türkçe 日本語

日本語 한어

한어 中文

中文 தாமில்

தாமில் فارسی

فارسی हिंदी

हिंदी Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Pilipino

Pilipino Indonesia

Indonesia தாமில்

தாமில்