WhatsApp: +65 91904616 E-mail: sales@sintec.sg

WhatsApp: +65 91904616 E-mail: sales@sintec.sg

Uncooled MWIR 128x128 pixels infrared camera with high-speed frame rates up to 4000 frames per second. Configurable ROI windowing (allows faster frame rates)

Features

Uncooled MWIR 128x128 pixels infrared camera with high-speed frame rates up to 4000 frames per second

Configurable ROI windowing (allows faster frame rates)

Maximum added value and affordability to ensure a full integration in the industry 4.0 applications

Multiple industrial applications: machine vision, laser process monitoring, gas detection, QA

Typical Applications

Additive manufacturing

Industrial process monitoring

Machine vision

Gas and flame detection

Spectroscopy

Glass manufacturing quality assurance

R&D industries

Automotive industry

Home appliance manufacturing

Metallurgy and steel industry

Petrochemical industry

Glass manufacturing industry

Specifications

Detector type: VPD PbSe FPA with digital interface, uncooled operation

Array format: 128x128 (16384 pixels)

Pixel size: 50x50um (square format)

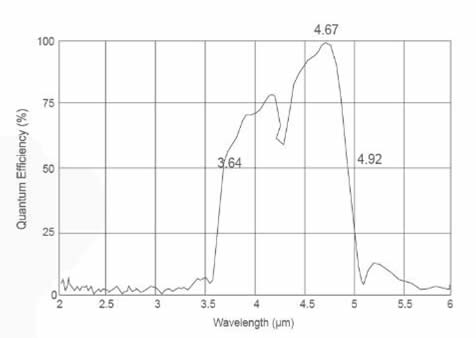

Spectral range: MWIR, 1.0μm to 5.0μm

Peak wavelength of detection: 3.7microns

Integration time: 10-1000μs, selectable

Raw data communication, 14 bit

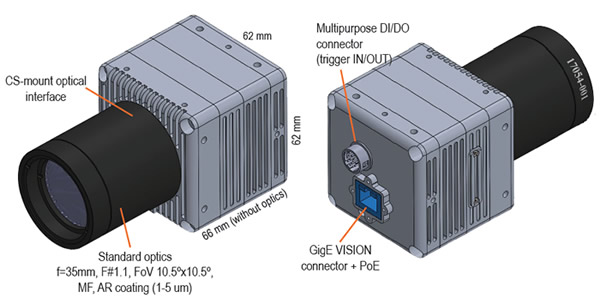

Interfaces: GigE version2.0 (GenICam compatible) with PoE; Multipurpose DI/DO connector (trigger IN/OUT) (cable sold separately)

Maximum frame rate: 4000fps

ROI windowing function

Mechanical shutter for 1-pt offset correction

Start-up time: < 10 seconds

Power supply: PoE, 8 W (non-PoE operation requires 12 VDC)

Metal housing with rear connectors and tripod screw holes (M3 and M4)

Dimensions and weight (w/o optics): 66(L)x62(W)x62(H)(mm), 400 grams

Optics (standard option): f=35 mm, F#1.1, FoV 10.5ºx10.5º, AR coating (1-5μm), manual focus with CS-mount interface

Software included: acquisition and visualization SW; SDK available for custom software programming

Minimum temperature of detection: 100ºC

| Part number | STN-16K | STN-16K+ |

| Maximum frame rate | 2000 images per second @ 128×128 Allows higher frame rates using embedded ROI windowing functions | 4000 images per second @ 128×128 Allows higher frame rates using embedded ROI windowing functions |

| Windowing modes | 128×128 64×64 (center of FPA) 32×32 (center of FPA) 1×128 (center of FPA) | Size and position of the ROI: configurable via SW |

| Acquisition mode | 128×128: Interlaced mode 64×64, 32×32, 1×128: Snapshot acquisition | All modes: Snapshot acquisition |

| NUC correction tables | Software correction | Hardware correction (4 tables stored) |

| Data transmission modes | RAW data, 14 bit | Selectable: – RAW data, 14 bit – NUC corrected, 16 bit – High-speed mode RAW/NUC: 12bit |

Features

Uncooled MWIR camera IP67-rated with industrial USB connection and 1 kHz frame rate

Optimized size and affordable cost to ensure a perfect integration in the production process: priced for cost sensitive machine vision applications!

Applications

Industrial manufacturing process control (welding, cutting, etc.)

Industrial automation

Laser process monitoring

Gas and fl ame detection

Machine vision

OEM integration

Industries

Automotive industry

Home appliance manufacturing

Metallurgy and steel industry

Glass manufacturing

Petrochemical industry

Specifications

Part number: STN-1024

Miniaturized uncooled infrared MWIR camera for industrial applications

Band of detection: MWIR (1 - 5 microns)

Peak wavelength of detection: 3.7 microns

FPA resolution: 32x32 (1024 pixels)

Shutter incorporated for 1-pt offset correction

Integration time: adjustment via software (100 – 500 us)

Maximum frame rate: 1000 Hz (slower rates are possible)

Global-shutter (snapshot) image acquisition

Electrical interface: USB powered, industrial M12 mini-USB connector in the back (optional: connector in the bottom part)

Communication interface: USB 2.0, high-speed (up to 480 Mbps)

Data transmission: raw data, 10 bits

Lens: f=24 mm, F#1.2, FoV 10.2ºx10.2º (IP67-rated)

Optional lens: f=48 mm, F#1.6, FoV 5.1ºx5.1º (IP67-rated)

Integrated temperature sensor

Dimensions (in mm): 98.0 (L) x 49.5 (W) x 61.0 (H) (connector in the back)

Weight: 250 grams

Minimum temperature of detection: 100 ºC

IP67-rated metal housing with CS-mount optics interface

Water-block and DLC coating for harsh environment

Software included: NIT SOFTWARE SUITE (Acquisition and visualization SW)

DLL for custom software development available

Inline infrared imaging monitoring system for industrial process monitoring

Continuous monitoring and measurement of the melt pool and heat-affected-zone (HAZ) geometry

Ensures quality monitoring

Allows coaxial integration and off-axis operation

Standalone operation

2-alarm levels configuration, PC data ogging

Main applications: laser welding, LMD, cladding, WAAM, others

| Part number | STN-I3MS |

| Components | Infrared camera with real-time processing electronics and waterblock connection box, multi I/O cable (3 m), power supply (24 VDC) Software package for system configuration, datalogging and log files analysis Infrared emitter for optical calibration |

| Process compatibility | Laser and arc welding, LMD, cladding, WAAM, others |

| Mechanical integration | Coaxial & off-axis operation |

| Laser optics compatibility (coaxial integration) | Transmission of infrared signal (above 1.1 um) from the process area to the optical port is required |

| Output | Analog signal output (0 VDC - 10 VDC) proportional to width of melt pool / HAZ Configurable span |

| Dimensions (mm) | Infrared camera: 88 mm x 60 mm x 92 mm Connection box: 124.5x102x28mm |

| Weight | 0.5 kg |

| Power supply | 24 VDC, 6 W; Power supply included |

| Imaging lens | CaF2, f=50 mm, F#2.25 with manual focus mechanism (other focal lengths available) |

| Mechanical enclosure (camera) | IP67 rated mechanical enclosure with embedded heatsink Embedded waterblock for air /water cooling |

| Mechanical interface (front side of optics) | C-mount thread with counter thread for tight adjustment |

| Field of view Resolution per pixel | Coaxial: dependent on the optical system installed in the laser optics Offaxis: FoV=3.7ºx3.7º (focal length f=50 mm) |

| Infrared camera | VPD PbSe camera, 64x64 pixels (pixel size: 50 microns) MWIR response (1 -5 um), frame rate 1000 images per second |

| Communication interface | Gigabit Ethernet (RJ-45) |

| Software | Acquisition and Configuration SW v.1.0; Visualization SW v.2.1 |

| Minimum requirements | PC with processor i5, RAM memory: 8 GB Hard disk available: 1 GB, O.S.: Windows 10 or later (32/64 bits) |

| Process monitoring configuration | Selectable configurations: manual, tracks, continuous track length (tracks mode), alarm levels, alarm delay laser ON delay & auto detection |

| Indicators | Melt pool / HAZ width, Infrared image, laser status, alarm (2 configurable alarm levels) |

| Other features | Laser ON/OFF digital input (opto-coupled) Monitoring alarm digital output (opto-coupled),process data logging, circular & rectangular region-of-Interest (ROI) |

| Accessories | 3-color light pole indicator |

Continuous monitoring and measurement of the melt pool geometry

Closed-loop control of the laser power during the complete process, ensuring quality and repeatibility

Compatible with most of laser optics and powders

Easy mechanical integration and quick configuration

Consistent operation, no need of reconfiguration during the process

Main applications: LMD and cladding

| Part number | STN-C |

| Components | Infrared camera with real-time processing electronics and waterblock connection box, multi I/O cable (3 m), power supply (24 VDC), software package for system configuration, data logging and log files analysis, infrared emitter for optical calibration |

| Process compatibility | LMD process (Laser Metal Deposition) cladding |

| Optical compatibility | Transmission of infrared signal (above 1.1 um) from the process area to the optical port is required |

| Material compatibility | Steel powder, Stainless steel powder, Stellite powder, Inconel, others |

| Laser power control | Analog signal output for laser power control, 0-10VDC |

| Dimensions (mm) | Infrared camera: 88x60xmm connection box: 124.5x102x28mm |

| Weight | 0.5 kg |

| Power supply | 24VDC, 6W, power supply included |

| Imaging lens | CaF2, f=50mm with manual focus mechanism (other focal lengths available) |

| Mechanical enclosure (camera) | IP67 rated mechanical enclosure with embedded heatsink Embedded waterblock for air /water cooling |

| Mechanical interface to laser optics | C-mount thread with counter thread for tight adjustment |

| Field of view Resolution per pixel | Dependent on the optical system installed in the laser head and diameter of the noozle |

| Infrared camera | VPD PbSe camera, 64x64 pixels (pixel size: 50 microns), MWIR response (1-5 um), frame rate 1000 images per second |

| Communication interface | Gigabit Ethernet (RJ-45) |

| Software | Acquisition and configuration SW v.2.0; Visualization SW v.2.1 |

| Minimum requirements | PC with processor i5, RAM memory: 8 GB; Hard disk available: 1 GB, O.S.: Windows 10 or later (32/64 bits) |

| Process control | Selectable modes: automatic, manual |

| Process configuration | Selectable process configuration: tracks, continuous, initial laser power, track length (tracks mode) laser ON delay & auto detection, feedback control parameters |

| Indicators | Melt pool width, laser power, infrared image, laser status |

| Other features | Laser ON/OFF digital input (opto-coupled); Monitoring alarm digital output (opto-coupled); Process data logging, Circular & rectangular region-of-interest (ROI) |

STL series MWIR camera is developed with resolution 640x512pixels, wavelength range 3.7~4.8um, standard CL connector, supporting standard analog PAL video and external trigger. The camera is Stirling refrigerator cooled and provides with 14bit and 117Hz output.

Digital image detail enhancement (DDE)

Low noise

14bit digital signal output

High stability, adapt to harsh environment

Short delivery time

The pictures on the right are the images with digital image detail enhancement (DDE turned on).

| Part number | STL-M640 | |

| Imaging | Detector | FPA MCT |

| Resolution | 640x512 | |

| Wavelength range | 3.7~4.8um | |

| F number | F2 | |

| NETD | 18mk | |

| QE | >70% | |

| Image cell | 15x15um | |

| Frame rate | 117Hz | |

| ROI | Window for higher frame rate | |

| Cooling | Striling refrigeration, lifetime 6000h; cooling 5min @ room temp; 8min @60oC | |

| Electrical | External trigger | TTL |

| Data port | Standard CL port, PAL | |

| Data output | Minicamera Link, digital, image AD16bit, ready for 14bit output | |

| Communication | RS422 series | |

| Input power | 24VDC, 30W@25 oC normal status | |

| Others | Weight | 3kg not incl. camera lens |

| Dimension | 222x117x98mm | |

| Operation temp. | -40 to +70oC | |

| Store temp. | -45 to +75 oC |

A leading supplier and manufacturer of a wide range of photonics products such as lasers,laser parts & machines.

Office: 10 Bukit Batok Crescent #07-02 The Spire Singapore 658079

Tel: +65 63167112

Fax: +65 63167113

Whatsapp: +65 91904616