A Spatial Light Modulator (SLM) is an electrically programmable device that modulates light according to a fixed spatial (pixel) pattern. SLM are typically used to control incident light in amplitude, phase, or the combination of both.

A Spatial Light Modulator (SLM) is an electrically programmable device that modulates light according to a fixed spatial (pixel) pattern. SLMs have an expanding role in several optical areas where light control on a pixel-by-pixel basis is critical for optimum system performance. SLMs are typically used to control incident light in amplitude, phase, or the combination of both.

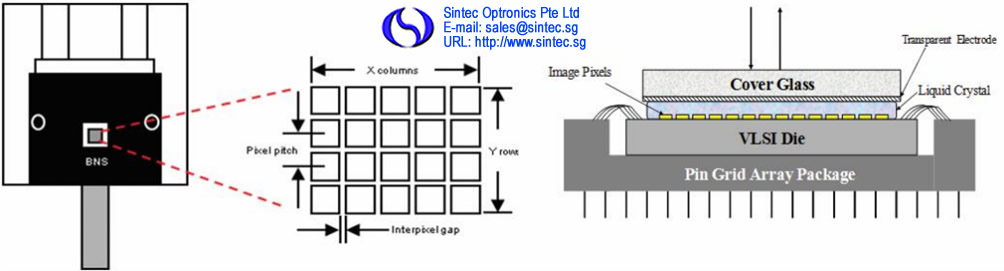

Several parameters help define SLM characteristics. Pixel pitch is defined as the center-to-center spacing between adjacent pixels. Interpixel gap describes the edge-to-edge spacing between adjacent pixels.

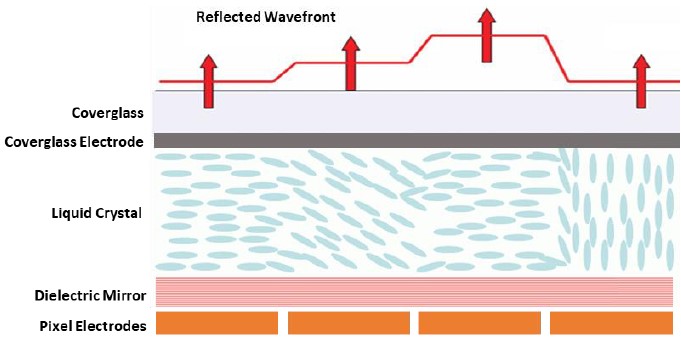

Polarized light enters the device from the top, passes through the cover glass, transparent electrode and liquid crystal layer, is reflected off the aluminum pixel electrodes, and returns on the same path. Drive signals travel through the pins on the bottom of the pin-grid array package, through the bond wires, and into the silicon die circuitry. The voltage induced on each electrode (pixel) produces an electric field between that electrode and the transparent electrode on the cover glass. This field produces a change in the optical properties of the LC layer. Because each pixel is independently controlled, a phase pattern may be generated by loading different voltages onto each pixel.

High Voltage Backplanes = Fastest Response Times

Our SLMs use custom backplanes, and proprietary drive schemes to achieve response times down to 1 ms (wavelength dependent). Most other liquid crystal spatial light modulators utilize display backplanes built with standard Nematic liquid crystal, limiting response time to >30 ms.

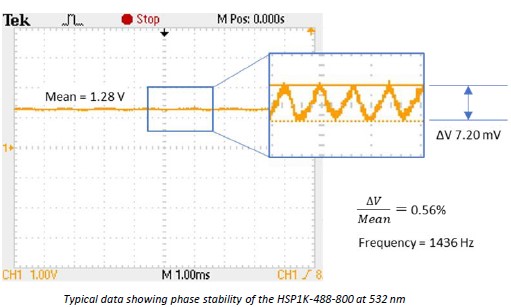

Highest Phase Stability Commercially Available –Our backplanes are custom designed to allow high refresh rates (up to 6 kHz), and direct analog drive schemes. Refreshing the voltage at the pixel at rates far surpassing the response time of the liquid crystal ensures high temporal phase stability. Further, use of direct analog drive schemes, as opposed to digital dithering, reduces optical flicker as low as 0.1% (0.001 π radians). Low Inter-pixel Cross Talk - Our backplanes are custom designed to offer high voltage at the pixel (5 – 12 V), and a large pixel pitch. Further, our SLMs are built with Meadowlark Optics proprietary liquid crystal which minimizes the required thickness of the LC layer in the SLM. By maximizing the ratio of pixel pitch to LC thickness we are able to offer SLMs with minimal inter-pixel effects.

Broad Wavelength Capabilities - We are the only SLM supplier capable of offering SLMs designed for use from UV (>365 nm) up to the LWIR (8 - 12 µm). Analog is Better - All the SLMs have been designed for phase modulation. Unlike many display LCoS backplanes which require a pulse width modulation (PWM) scheme, our backplanes utilize analog voltages at each pixel. This results in a very stable phase response over time.

High Bit Depth Controllers - we offer 8, 12, and 16-bit controllers to provide the most linear resolvable phase levels commercially available (up to 500). Fast transfer speeds from the computer to the SLM are offered up to 2 kHz.

Polarized light enters the device from the top, passes through the cover glass, transparent electrode and liquid crystal layer, is reflected off the aluminum pixel electrodes, and returns on the same path. Drive signals travel through. There are 2 types of special light modulators: reflective analog SLMs and transmissive SLMs.

Reflective Analog SLMs: All of our liquid crystal on silicon (LCoS) backplanes incorporate analog data addressing with high refresh rates to provide the lowest phase ripple SLMs available. User’s can select standard or high speed liquid crystal for optimal performance. Liquid cooling systems are available to remove heat via the back of the SLM chip in order to maximize optical power handling capabilities:

Transmissive SLMs: All of our liquid crystal on glass (LCoG) SLMs enable simple optical systems when low pixel counts are sufficient. Users can select single-mask or configurations for phase or amplitude modulation, or a dual-mask configuration for combined phase and amplitude modulation. (Removed, just for reference)

We have 2 types of Spatial Light Modulators:

Spatial Light Modulator -1024 x 1024

Spatial Light Modulator -1920 x 1200

High Speed Analog, Phase Only –up to 2 kHz

Our Liquid Crystal on Silicon (LCoS) Spatial Light Modulators (SLMs) are uniquely designed for pure phase applications and incorporate analog data addressing with high refresh rates (1400 Hz). This combination provides users with the fastest response times with high phase stability. We offer High Speed SLM 1024x1024 and Ultra High Speed SLM 1024 x 1024 which is good for applications requiring high speed, high diffraction efficiency, low phase ripple and high-power lasers.

SLM Features:

High resolution

High speed

High phase Stability

Pure analog phase control

High first order efficiency

High reflectivity

High power handling

On-board Memory

Wavelengths from 488–1650 nm

Software Features:

Input and output triggers

Image generation

Automated sequencing

Wavefront calibration

Global and regional look up tables

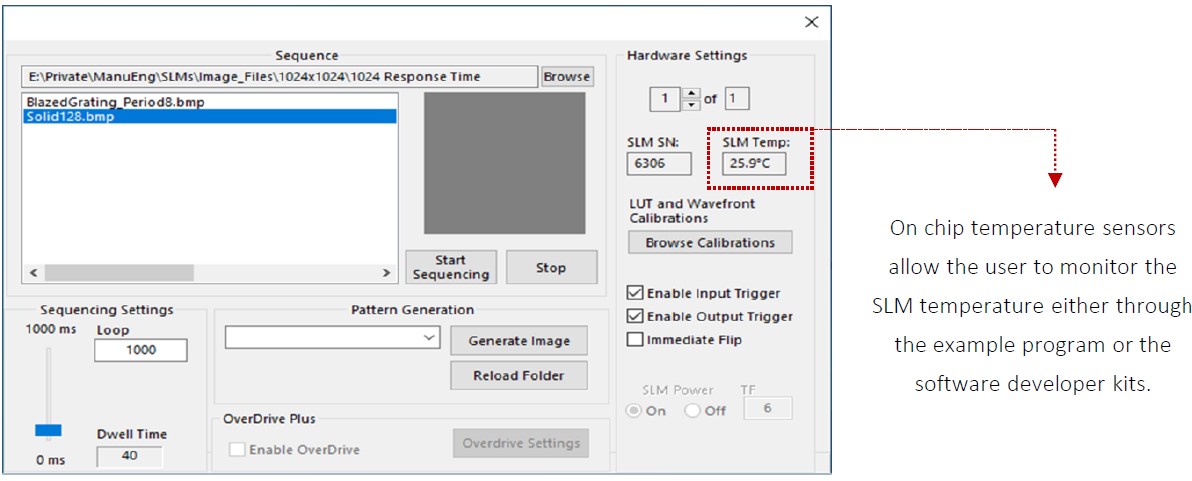

Temperature Monitoring

Look-up-table Calibration Kit

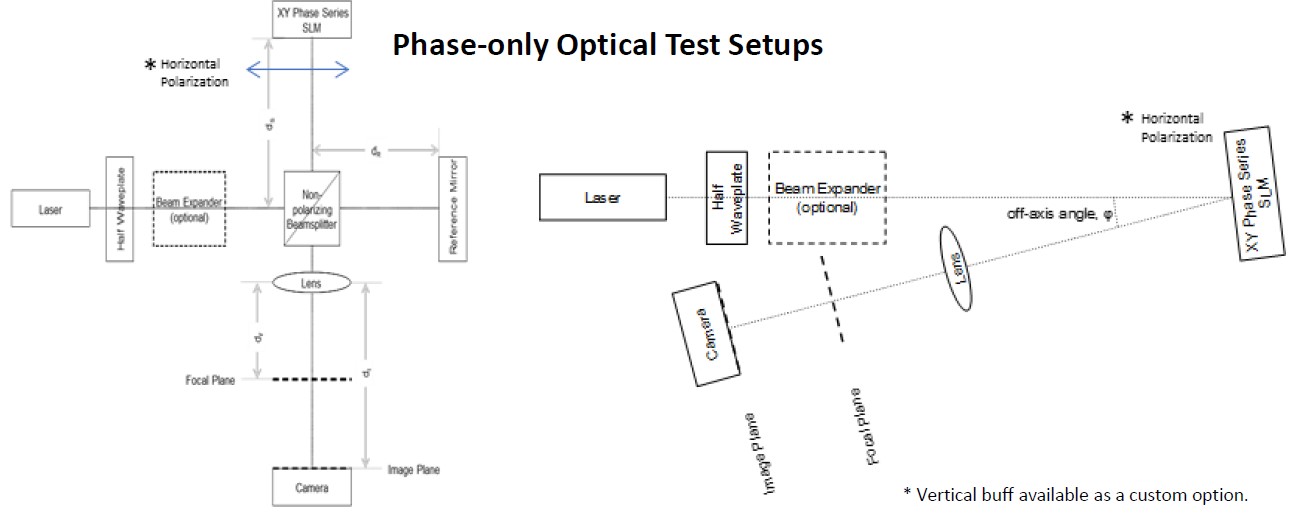

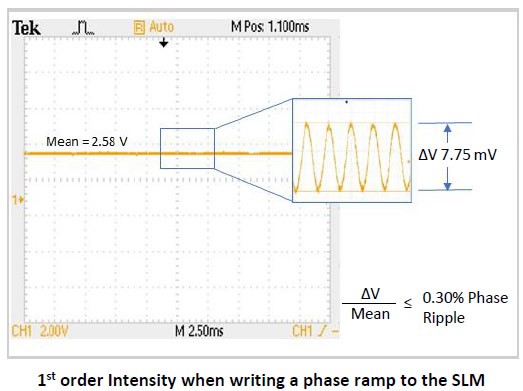

High Phase Stability -Making an LCOS SLM faster usually means the phase stability is worse. However, we’ve combined our traditional analog drive scheme with new proprietary technologies to suppress phase instabilities to 0.05% to 2.0% without compromising speed. Phase ripple is quantified by measuring the variation in intensity of the 1st order diffracted spot as compared to the mean intensity while writing a blazed phase grating to the SLM. Since phase stability varies as a function of pixel voltage, this measurement approach is an average and does not represent all scenarios. If your application requires extremely low phase ripple, please contact us for more information on the 19x12 SLM.

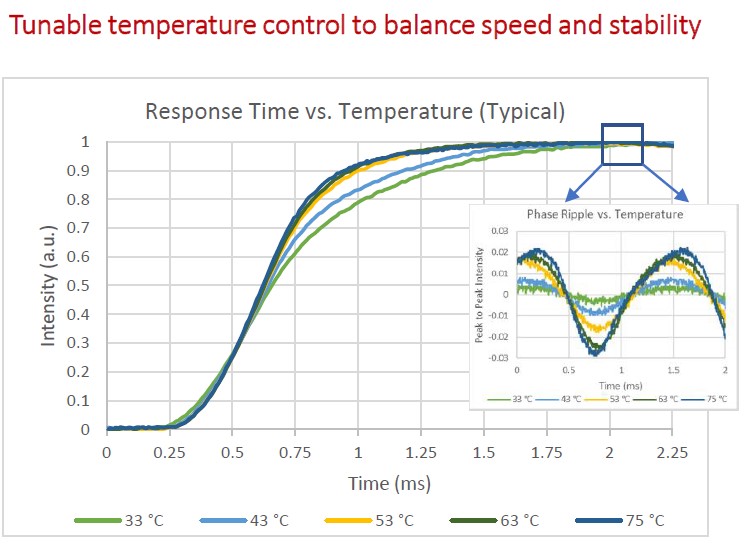

High Speed with High Phase Stability -Great care was taken in the design of the 1024 x 1024 silicon backplane to enable high speed operation while simultaneously maximizing phase stability. The 1024 x 1024 SLM is incredibly fast with liquid crystal response times ranging from 0.6 to 8 ms (wavelength dependent) for a full wave of modulation. In our ultra-high speed model customers can control the temperature set point to find the perfect balance between switching speed and phase stability.

Sub-millisecond liquid crystal response times are measured in the far field. Images applied to the SLM are toggled between an 8-pixel, 2π phase grating and a solid image. Data captured while operating from 33°C to 75°C, using 10 to 90% reference levels. Results show typical switching speeds and phase stability at 532 nm.

TEC Heater (Part Number TCS2)

Thermoelectric Cooler (TEC) gives the user control over the temperature in which to operate the SLM. Heating the liquid crystals increase the switching speed, and cooling the liquid crystals improves phase stability.

Diffraction Efficiency (0th-order)

This is the amount of light retained in the 0th order (dc) when writing solid grayscale images to the SLM as compared to the amount of light in the 0th order when the SLM is replaced with a reference mirror. This measurement quantifies losses in the coverglass coatings, losses due to wavelength dependent reflectivity of the pixel pads, as well as losses to diffraction from reflecting off the pixilated structure of the backplane. In the case of a dielectric mirror coated model, the measurement accounts for losses due to imperfect reflectivity of this dielectric mirror coating. The 0th order diffraction efficiency will vary as a function of wavelength due to differences in coating materials and designs. It will also vary with pixel value due to the inherent change in the index of refraction of the liquid crystal that results in a change in the Fresnel reflections inside the liquid crystal cell. Most standard SLMs will range from 70 90%, while the dielectric mirror coated models will range from 92-98%.

High Efficiency Dielectric Mirror Coating

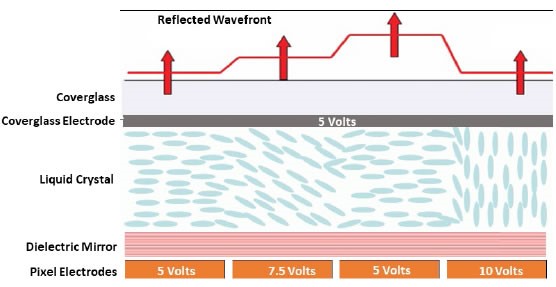

Optically, the backplane is converted into a flat dielectric mirror by depositing dielectric layers to eliminate the amplitude and optical path variations associated with the underlying aluminium pixel structure. The dielectric stack is kept thin to minimize any drop in electric field across the LC layer as shown in the figure below.

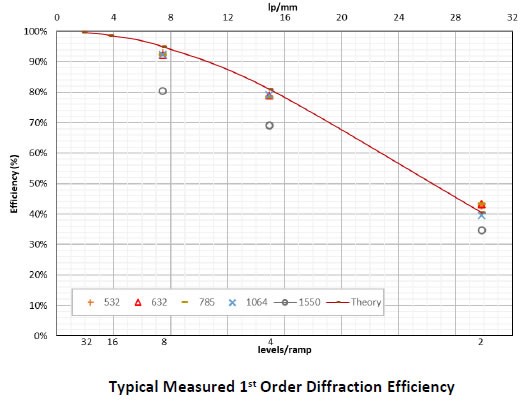

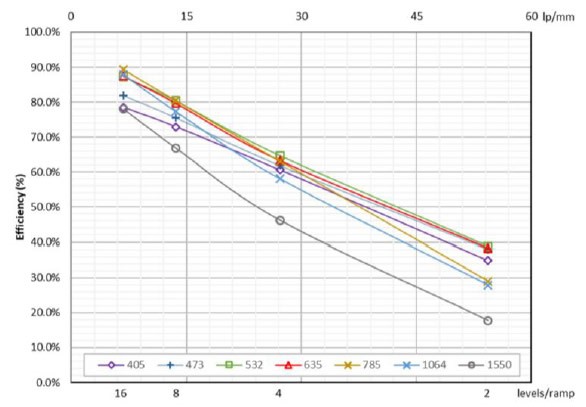

Diffraction Efficiency (1st-order)

This is the percentage of light measured in the 1st-order when writing a linear repeating phase ramp to the SLM as compared to the light in the 0th order when no pattern is written to the SLM. 1st-order diffraction efficiency varies as a function of the number of phase levels, or pixels, in the phase ramp. Example measurement data taken at various wavelengths is shown below for phase ramps with 2 to 8 phase levels between 0 and 2π.

Software -Our SLMs are supplied with a graphical user interface and software development kits that support LabVIEW, Matlab, Python, and C++. The software allows the user to generate images, to correct aberrations, to calibrate the global and/or regional optical response over ‘n’ waves of modulation, to sequence at a user defined frame rate, and to monitor the SLM temperature.

Global or Regional Calibrations -Regional calibrations provide the highest spatial phase fidelity commercially available by regionally characterizing the phase response to voltage and calibrating on a pixel-by-pixel basis.

Image Generation Capabilities-

Bessel Beams: Spiral Phase, Fork, Concentric Rings, Axicons

Lens Functions: Cylindrical, Spherical

Gratings: Blazed, Sinusoid

Diffraction Patterns: Stripes, Checkerboard, Solid, Random Phase

Holograms, Zernike Polynomials, Superimpose Images

Optional Look Up Table Calibration Kit (Part Number LUT1)

We include a calibrated LUT at one of our standard test sources (405, 532, 635, 785, 1064, or 1550 nm). If the user wants to work at a different wavelength, we recommend purchasing our Look Up Table Calibration Kit. It provides the tools needed to create a custom LUT based on the user’s wavelength and operating temperature for optimal performance. The kit is shipped with software and a National Instruments NI 6000 data acquisition card. The user only needs to provide a photodetector at their desired wavelength.

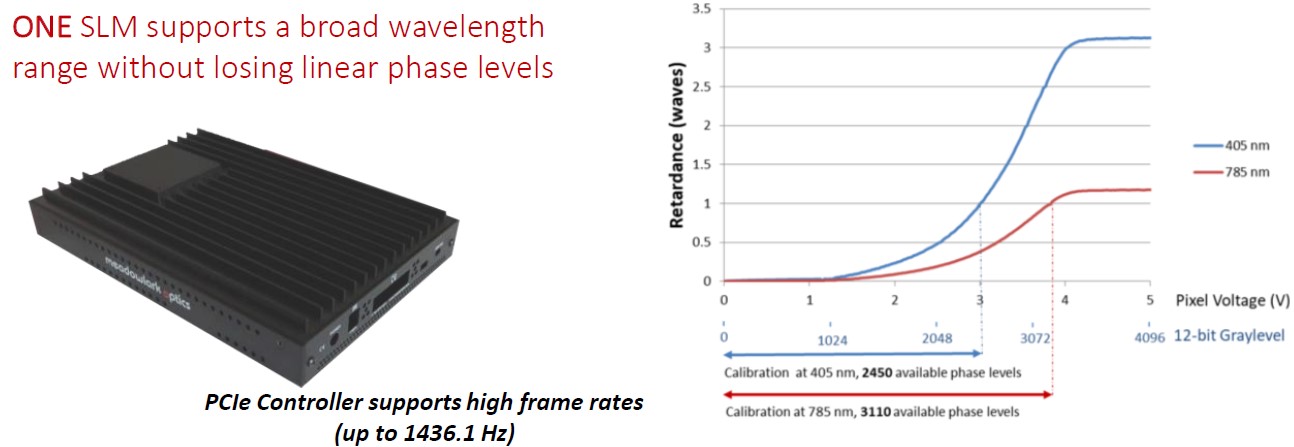

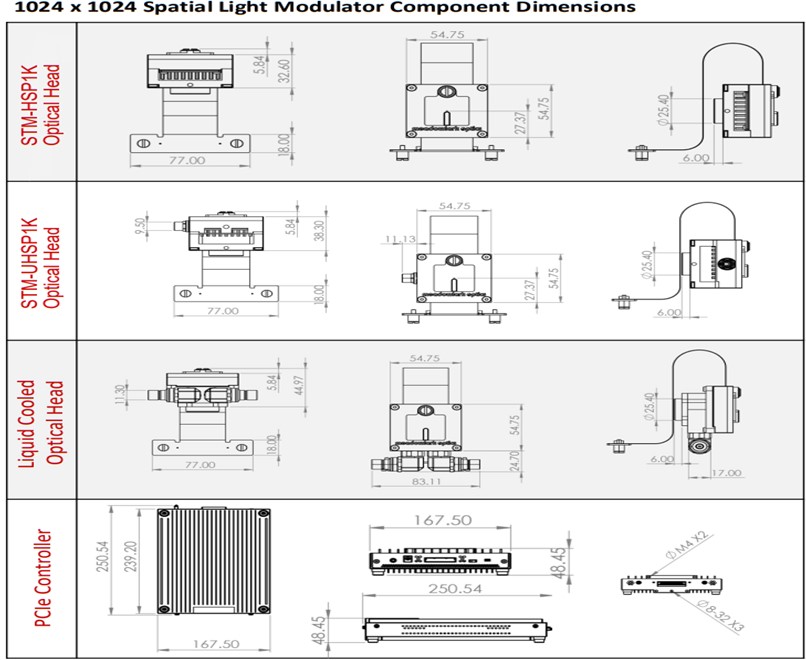

Hardware Interface-The 1024 x 1024 SLM system includes a Gen3 x8 PCIe controller with input and output triggers and low latency image transfers. Triggering can be performed on SLM chip refresh period boundaries of 696 µs, or even in the middle of refresh periods for applications requiring the SLM be tightly synchronized to external hardware. The controller also includes 752 frames of internal memory that can be loaded in advance, then sequenced at full speed in order to minimize traffic on the PCIe bus during operation. Using the 8bit input/12 bit out design enables the SLM to support a broad wavelength range without sacrificing linear phase levels

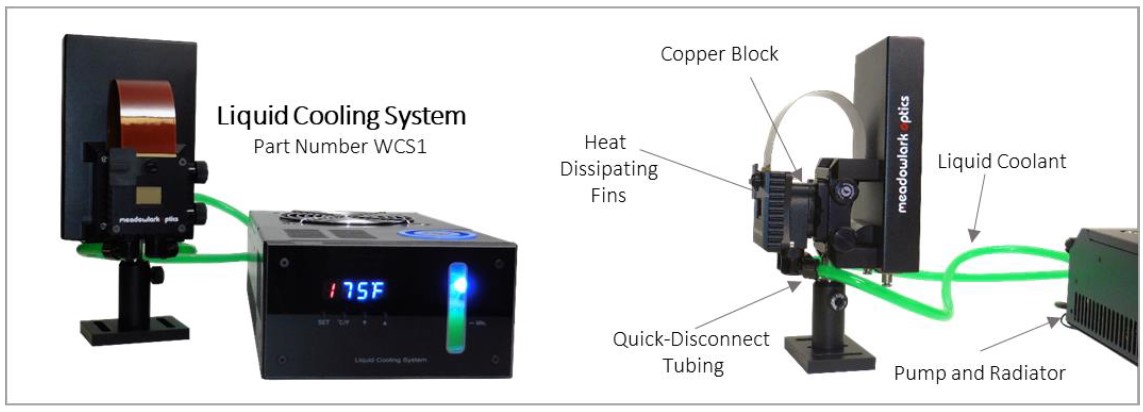

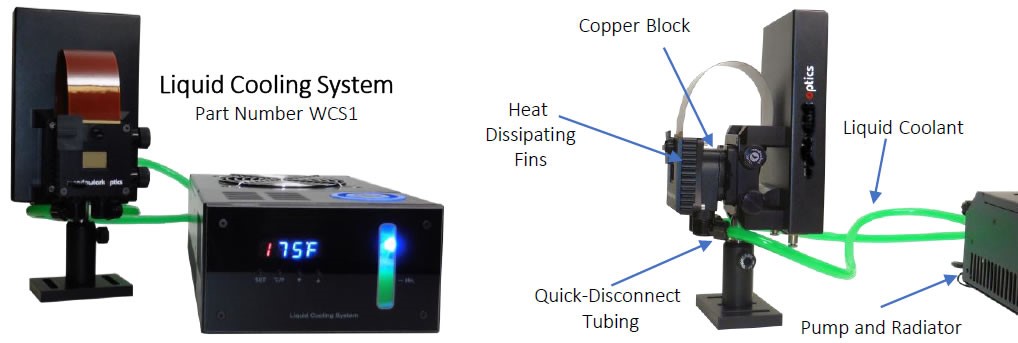

High Power Capability-Our SLMs are designed for compatibility with high power lasers through use of low absorption materials, large pixel pads, dielectric mirror options, and liquid cooling. If you are using a high power please contact us with more information about your average power, pulse width, repetition rate, and beam diameter incident on the SLM. We will compare your laser specifications to our catalogue of collected measurements and make a recommendation for the power handling limit of your optical system.

Liquid Cooling System- A copper block is attached to the back of the optical head to draw heat out of the SLM chip. The copper block is coupled via 2 meters of quick disconnect tubing to cooling unit containing an external pump, radiator, and fan to cool the liquid down to ambient temperature Includes one bottle of liquid coolant The liquid cooling system not only pulls heat away from the SLM, it also keeps the SLM at a consistent temperature to ensure no change in modulation occurs as temperature varies.

1.1 High Speed SLM 1024x1024 Specification (Parts no. STM-HSP1K-XXX-XXX-PC8)

Resolution: 1024 x 1024

Array Size: 17.40 x 17.40 mm

Zero-Order Diffraction Efficiency: 75 -87%

Fill Factor: 97.2%

Pixel Pitch: 17 x 17 μm

With Dielectric Mirror Coating:92 –98%

| Standard calibration wavelength | HIGH SPEED Liquid Crystal Response Time | Calibrated wavefront distortion | ||

| AR coating range 488-850nm | AR coating range 500-1200nm | AR coating range 850-1650nm | ||

| 532 nm | ≤ 1.0 ms | ≤ 1.4 ms | – | λ/5 |

| 635 nm | ≤ 1.3 ms | ≤ 1.8 ms | – | λ/6 |

| 785 nm | ≤ 1.8 ms | ≤ 2.4 ms | – | λ/7 |

| 1064 nm | – | ≤ 3.4 ms | ≤ 5.5 ms | λ/10 |

| 1550 nm | – | – | ≤ 8.0 ms | λ/12 |

| Part number | STM-HSP1K-488-850-PC8 | STM-HSP1K-500-1200-PC8 | STM-HSP1K-850-2650-PC8 | |

1.2 Ultra High Speed SLM 1024x1024 (Parts no. STM-UHSP1K-XXX-XXX-PC8)

Resolution: 1024 x 1024

Array Size: 17.40 x 17.40 mm

Zero-Order Diffraction Efficiency: 75 -87%

Fill Factor: 97.2%

Pixel Pitch: 17 x 17 μm

With Dielectric Mirror Coating:92 –98%

| Standard calibration wavelength | ULTRA HIGH SPEED Liquid Crystal Response Time | Calibrated wavefront distortion | ||

| AR coating range 488-850nm | AR coating range 500-1200nm | AR coating range 850-1650nm | ||

| 532 nm | ≤ 0.6 ms | ≤ 0.7 ms | – | λ/5 |

| 635 nm | ≤ 0.7 ms | ≤ 0.9 ms | – | λ/6 |

| 785 nm | ≤ 0.9 ms | ≤ 1.2 ms | – | λ/7 |

| 1064 nm | – | ≤ 1.7 ms | ≤ 2.0 ms | λ/10 |

| 1550 nm | – | – | ≤ 3.9 ms | λ/12 |

| Part number | STM-UHSP1K-488-850-PC8 | STM-UHSP1K-500-1200-PC8 | STM-UHSP1K-850-2650-PC8 | |

E-Series: Educational, Economical & Entry- level

We are pleased to introduce our latest E-Series Spatial Light Modulator (SLM). Don’t let the name fool you; with improved specifications over our previous model, it is anything but entry-level. It is, however, economical and ideally suited for educational labs with a limited budget. Liquid Crystal on Silicon (LCoS) Spatial Light Modulators (SLMs) are uniquely designed for pure phase applications and incorporate analog data addressing with high refresh rates. This combination provides users with the fastest response times and highest phase stabilities commercially available. We offer both transmissive and reflective SLMs in either one - or two - dimensions. Phase - only SLMs can also be used for amplitude - only or a combination of both.

SLM Features:

High resolution

High phase stability

Pure analog phase control

High first order efficiency

High reflectivity

High power handling

Compact design

Wavelengths from 400–1650 nm

Software Features

Output triggers

Image generation

Automated sequencing

Wavefront calibration

Global and regional look up tables

High Phase Stability – We are known for having the fastest SLMs with the least amount of phase ripple on the market. Our backplanes are custom designed with high refresh rates and direct analog drive schemes, resulting in phase ripple for most configurations between 0.10 - 0.30%, with some configurations around 1-2%. For customers who require even better performance, customization is possible with phase ripple as low as 0.025% (0.0008 π radians). Phase ripple is quantified by measuring the variation in intensity of the 1st order diffracted spot as compared to the mean intensity while writing a blazed phase grating to the SLM.

Hardware Interface Options - The 1920 x 1200 SLM is offered with a 60 Hz HDMI Controller enabling customers to take advantage of our fast liquid crystal response times. Standard hardware includes output trigger for synchronization.

Diffraction Efficiency (1st - order) - This is the percentage of light measured in the 1st - order when writing a linear repeating phase ramp to the SLM as compared to the light in the 0th order when no pattern is written to the SLM. Diffraction efficiency varies as a function of the number of phase levels in the phase ramp. The plot to the right shows sample 1st order diffraction efficiency measurements, as a function of the phase ramp period, taken at various wavelengths.

Diffraction Efficiency (0th-order) - This is the amount of light measured in the 0th-order (dc) when the SLM is written with various solid gray levels as a percentage of the amount of light measured when the SLM is replaced with a reference mirror. Therefore, it takes into account losses in transmission through the coatings on the SLM cover window, as well as diffraction losses due to the pixel pads being less than 100% fill-factor. In addition to these losses, this measurement also accounts for losses due to imperfect reflectivity of the aluminium pixel mirrors, or in the case of a dielectric mirror coated model the measurement accounts for losses due to imperfect reflectivity of this dielectric mirror coating. The 0th-order diffraction efficiency will vary as a function of wavelength due to differences in coating materials and designs. It will also vary with pixel value due to the inherent change in the index of refraction of the liquid crystal that results in a change in the Fresnel reflections inside the liquid crystal cell. Most standard SLMs will range from 70 – 90%, while the dielectric mirror coated models will range from 92 – 98%.

High Efficiency Dielectric Mirror Coating - All the light reflecting off the SLM is modulated – including the light between the aluminium pixel electrodes. The reflective pixel structure associated with a LCoS SLM backplane acts as an amplitude grating diffracts some light into higher orders. Optically, the active area of the backplane is converted into a flat dielectric mirror by depositing dielectric layers to eliminate the amplitude and optical path variations associated with the underlying aluminium pixel structure. The dielectric stack is kept thin to minimize any drop in electric field across the LC layer as shown in the figure below. In other words, there are no abrupt changes in phase modulation (such as dead zones) between pixels due to the smoothing which results from separating the LC modulator from the driving electrodes.

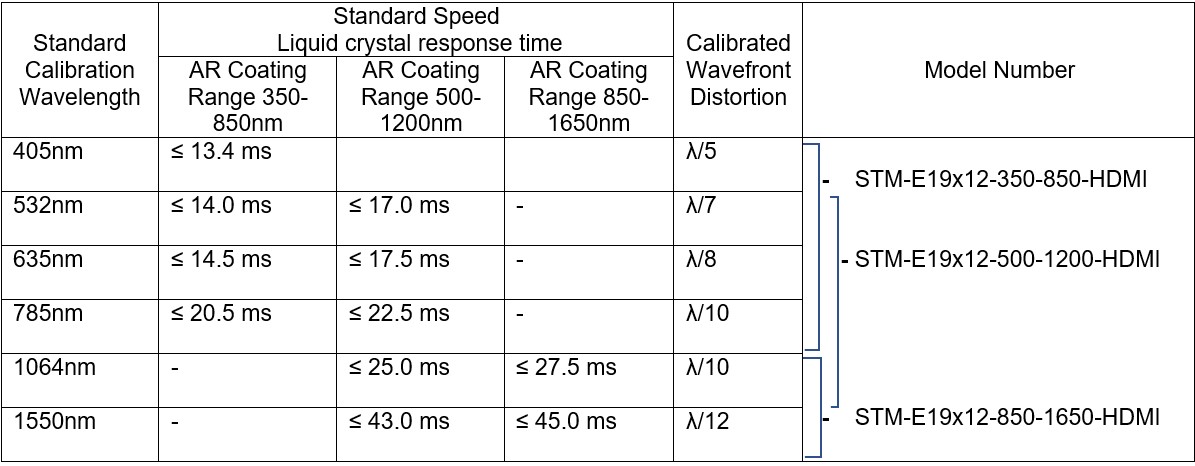

1920 x 1200 Analog Spatial Light Modulator Specifications

Resolution: 1920 x 1200

Array Size: 15.36x9.60 mm

Pixel Pitch: 8.0x8.0 µm

Backplane Refresh: 1.35 kHz

Fill Factor: 95.6%

0th Order Diffraction Efficiency: 76 - 91%

0th Order Diffraction Efficiency: 92 – 98% (dielectric mirror)

Controller: HDMI

Software - Our SLMs are supplied with a Graphical User Interface and software development kits that support LabVIEW, Matlab, Python and C++. The software allows the user to generate images, to correct aberrations, to calibrate the global and/or regional optical response over ‘n’ waves of modulation, to sequence at a user defined frame rate, and to monitor the SLM temperature.

Global or Regional Calibrations - Regional calibrations provide the highest spatial phase fidelity commercially available by regionally characterizing the phase response to voltage and calibrating on a pixel-by-pixel basis.

Image Generation Capabilities

Bessel Beams: Spiral Phase, Fork, Concentric Rings, Axicons

Lens Functions: Cylindrical, Spherical

Gratings: Blazed, Sinusoid

Diffraction Patterns: Stripes, Checkerboard, Solid, Random Phase, Holograms, Zernike Polynomials, Superimpose Images

Spatial Light Modulator System Add-ons-

Liquid Cooling System- copper block is attached to the back of the optical head to draw heat out of the SLM chip. The copper block is coupled via 2 meters of quick-disconnect tubing to cooling unit containing an external pump, radiator and fan to cool the liquid down to ambient temperature. Includes one bottle of liquid coolant.

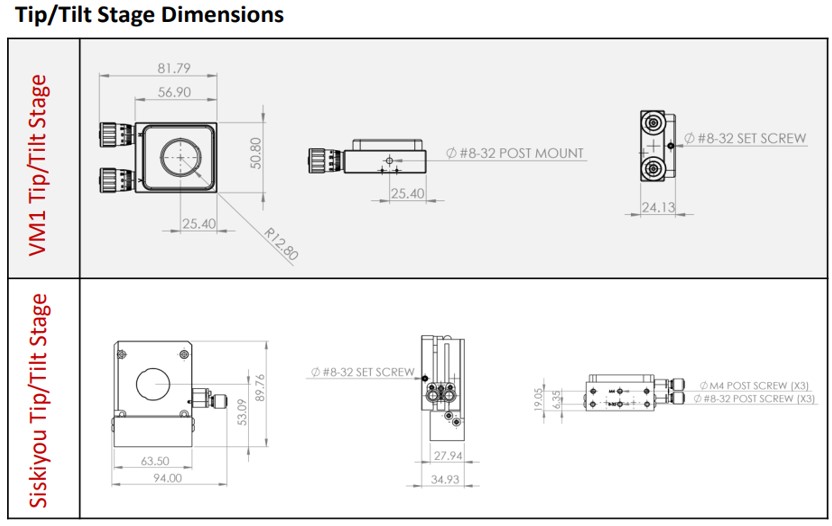

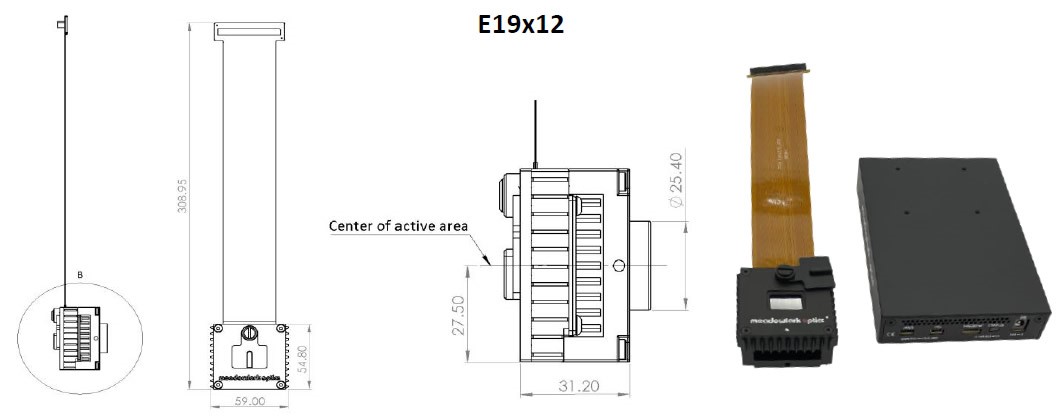

Dimensions of E19x12:

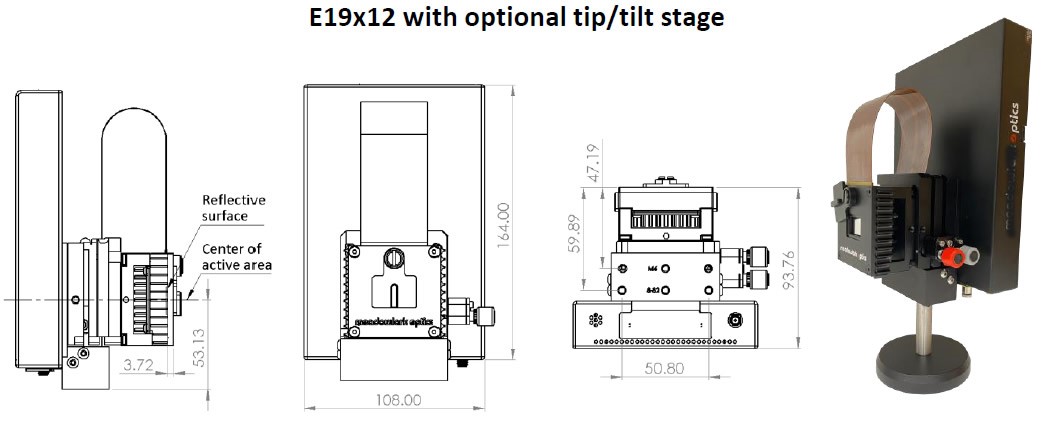

Dimensions of E19x12 with optional tip/tilt stage:

Application Notes: 3D Mapping of Neural Circuits In Vivo Opens the Window on Neurological Disease

A leading supplier and manufacturer of a wide range of photonics products such as lasers,laser parts & machines.

Office: 10 Bukit Batok Crescent #07-02 The Spire Singapore 658079

Tel: +65 63167112

Fax: +65 63167113

Whatsapp: +65 91904616