WhatsApp: +65 91904616 E-mail: sales@sintec.sg

WhatsApp: +65 91904616 E-mail: sales@sintec.sg

Our flat meta lenses are perfect for laser processing tools. They provide extended depth-of-field, making it easy to mark a variety of objects with precision. Whether you need to mark a metal part with a serial number or weld a plastic part together, this lens will make the job easy. It is a new generation of ultralight, low cost, high performance metalens surfaces.

Our flat lenses are perfect for laser processing tools. They provide extended depth-of-field, making it easy to mark a variety of objects with precision. Whether you need to mark a metal part with a serial number or weld a plastic part together, this lens will make the job easy. It is a new generation of ultralight, low cost, high performance metalens surfaces.

Our lenses are perfect for applications where high resolution over an extended depth of field is required. Each lens has a very low profile, making it easy to integrate into your system. It is also customizable for any laser wavelength and beam diameter, making it perfect for your needs. Our lenses are carefully crafted via lithography to provide the best results each time. With our lenses, you can experience enhanced precision, quality, and reliability in a variety of laser processing tools.

We have created an advanced optical surface design technology that enables ultralight, low cost and high performance metalens surfaces. Our domain expertise in optical design and high precision volume manufacturing allows us to deliver optical performance and capability previously unachievable with traditional refractive, diffractive or metalens methods.

1. STOB Series Flat Meta Lenses for Extended Depth of Field

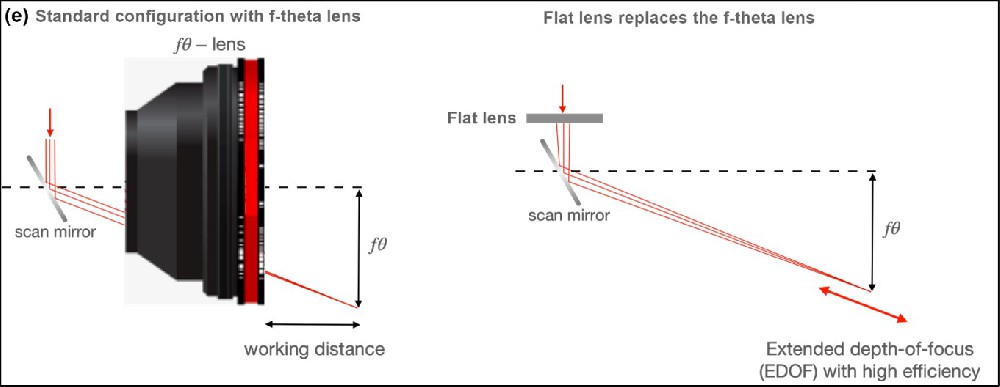

Flat meta lenses are perfect for laser processing tools, they provide extended depth-of-field, making it easy to mark a variety of objects with precision. Whether you need to mark a metal part with a serial number or weld a plastic part together, this lens will make the job easy. This lens boasts the following advantages:

Extended depth of field (>75 mm)

Excellent PSF performance

Ultralow profile

Low-cost, large volume manufacturing

Customizable for any laser wavelength

Tolerant to high laser fluences

Specifications:

| Optical Specifications | |

| Wavelength | 1064nm |

| EFL | 195-270mm |

| DOF (extended) | 75mm |

| Lens Diameter | 3mm |

| Transmission Efficiency | >90% |

| Tolerant to High Laser Power | |

| Mechanical Specifications | |

| Diameter | 3mm |

| Thickness | <1mm |

| Weight | <1gram |

| PSF Spot Size (FWHM) | |

| 195mm from lens | 78μm |

| 225mm from lens | 103 μm |

| 270mm from lens | 98 μm |

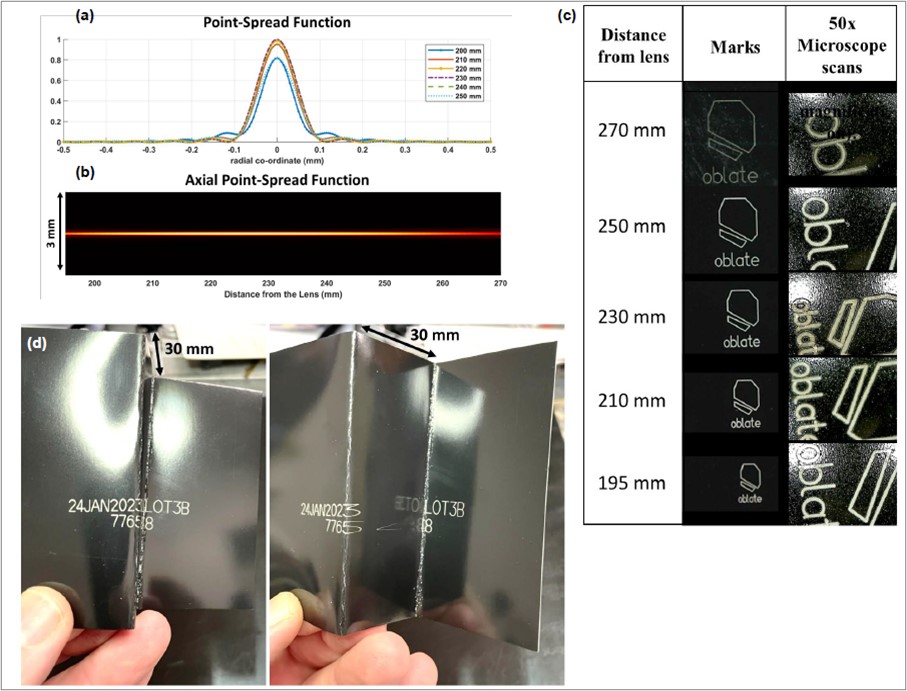

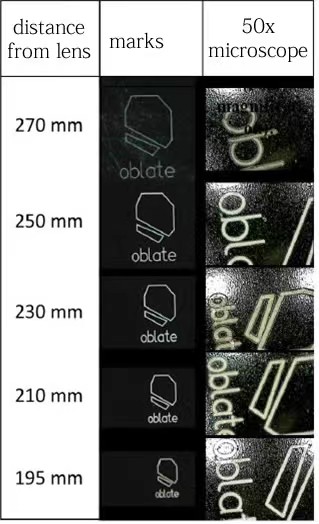

The performance of the extended depth of field (EDOF) flat lens is shown below. The calculated Point-Spread Function (PSF) shows good focusing for the extended depth of focus range in Fig. (a). The calculated PSF as a function of distance from the lens is also shown in Fig. (b). To the right Fig. (c), standard black-card mark tests are shown from 195 - 270 mm from the lens as well as microscope scans of the marks (50x magnification). No refocusing was performed as the target distance was changed. While the size of the mark varies due to galvo drawing, the spot size remains uniform. In the lowermost photographs Fig. (d), a standard black-card mark test was made on a folded card where the two surfaces of the card were spaced 30 mm apart. The markings are clear and distinct on both surfaces.

Ordering number:

STOB-EDF-WW-XX-YY

WW : wavelength

XX : effective focal length (EFL)

YY : Depth of focus

Example: STOB-EDF-1064-195-55

Wavelength = 1064nm

EFL =>195mm

Depth of field = 55mm

The table showing some of our capability is below

| Wavelength | EFL | DOF | Diameter | Spot Size |

| 355 nm | 25 - 100 mm | 25, 50 mm | 3 - 6 mm | 25 - 250 um |

| 532 nm | 25 - 100 mm | 25, 50 mm | 3 - 6 mm | 25 - 250 um |

| 1064 nm | 25 - 100 mm | 25, 50 mm | 3 - 6 mm | 25 - 250 um |

| 10.6 um | 25 - 100 mm | 25, 50 mm | 3 - 6 mm | 50 - 250 um |

For ordering a metalens, please tell us your requirements on laser wavelength, effective focal length, depth of focus, beam diameter, required focal beam diameter and quantity.

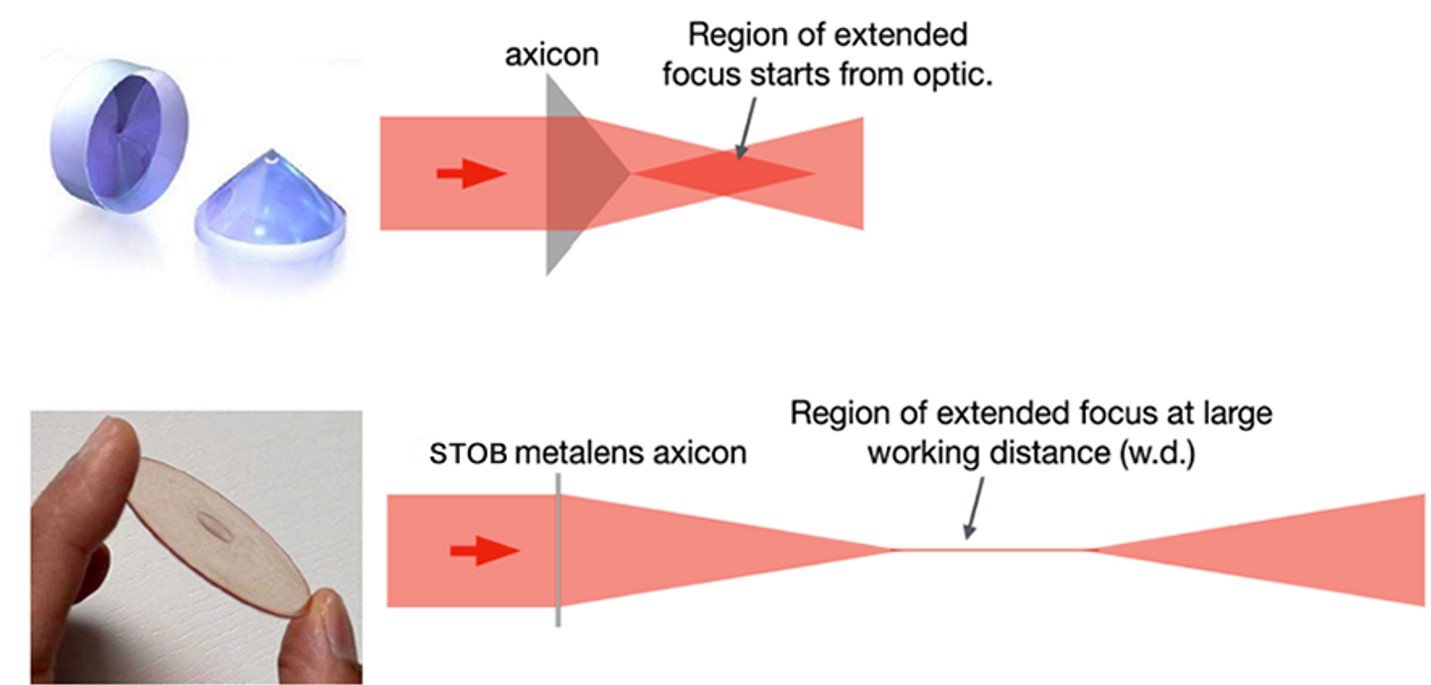

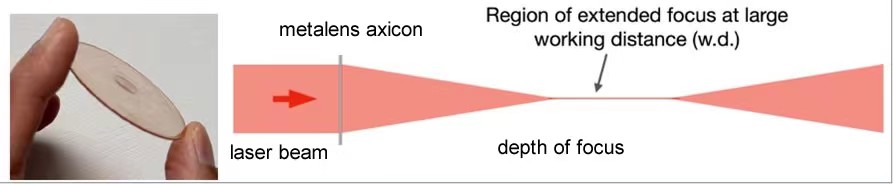

2. STOB Series Metalens Axicon Lenses for Extended Depth-of-field Application

We are the exclusive manufacturer of metalens axicon lenses suitable for applications where high resolution over an extended depth-of-field is desired. Applications include laser marking, machining, welding, microscopy, imaging & ophthalmology.

Such lenses afford the following advantages:

Extended depth-of-focus (for example >70mm @ w.d. of 125mm).

No need for slow & expensive refocusing mechanisms.

Larger working distances than conventional axicons (>250mm possible)

Uniform peak intensity over the extended depth-of-focus (DOF)

High efficiency & diffraction-limited spot sizes.

Low cost, thin (<1mm) & lightweight (1g)

Customizable for any laser wavelength & beam diameter

Tolerant to high laser fluences

The following lens specification are representative of our axicon metalens technology capability. Please contact us for other specifications.

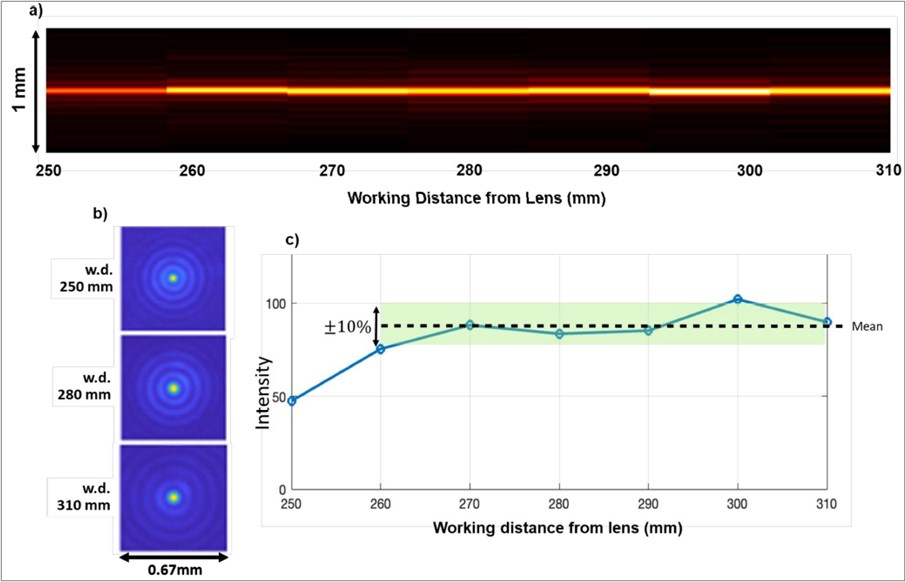

| Part Number | STOB-1064-6-280 |

| Wavelength | 1064nm |

| Diameter | 6mm |

| EFL | 280mm |

| DOF (extended) | 50mm |

| Spot Size (FWHM) | <67 µm |

| On-Axis Intensity Variation | +/- 10% |

Experimental Data

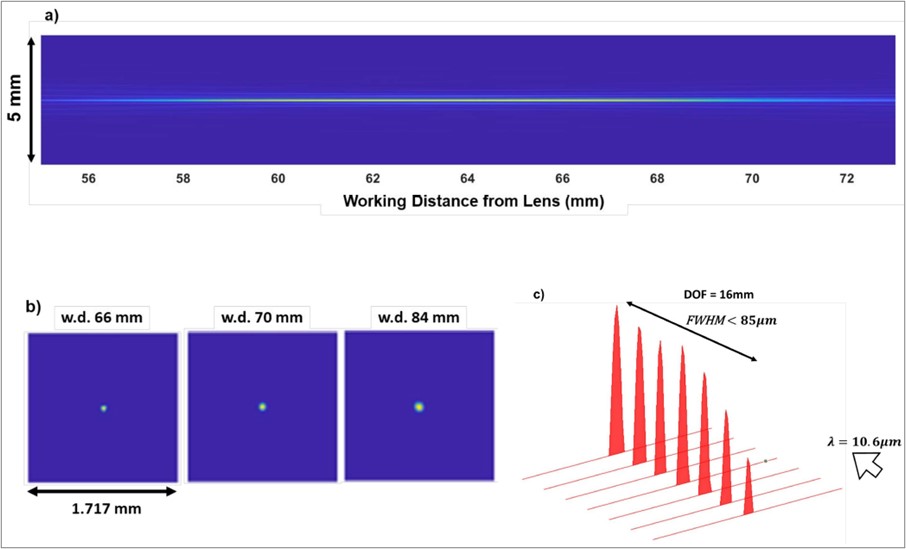

a) Axial Point-Spread Function

b) Point-Spread Function at three distances from the lens,

c) Peak intensity of on-axis spot. Variation along the working distance is +/-10%

| Part Number | STOB-10.6-8-64 |

| Wavelength | 10.6 µm |

| Diameter | 8mm |

| EFL | 64mm |

| DOF (extended) | 16mm |

| Spot Size (FWHM) | <85 µm |

Experimental Data and Compute Simulations

a) Computer simulation of axial point-spread function

b) Experimental data of point-spread function at three distances from the lens

c) Experimental data showing measured depth of field and FWHM of spot size.

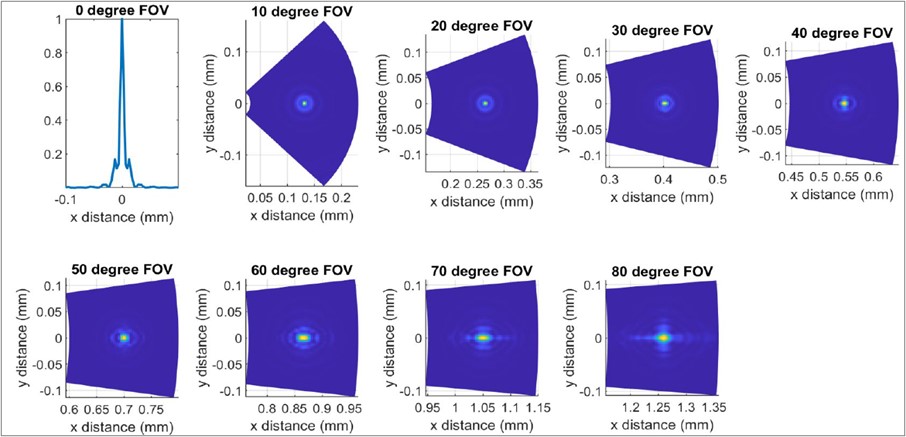

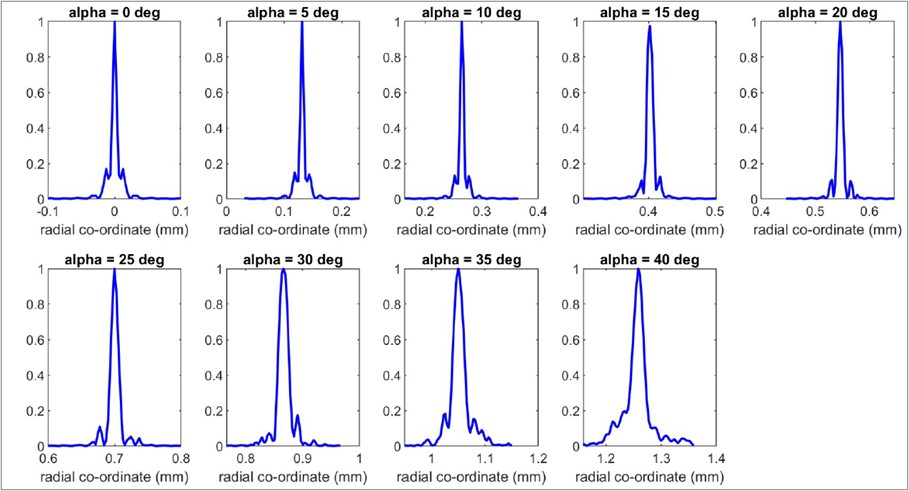

3. STOB Series FOV Infrared Lenses for Time-of-Flight Applications

We have designed and built an ultra-low profile diffractive metalens suitable for applications where an extended field of view is required. This technology boasts the following advantages:

Field of view of 80 degrees

Excellent PSF performance

Ultralow TTL (< 2.5 mm)

Low-cost, large volume manufacturing

Customizable for any wavelength

The following lens specifications are representative of our infrared metalens technology capability. Please contact us for custom requirements and design capabilities.

Specifications of the STOB Series Infrared TOF metalens with Large Field of View

| Optical Specifications | |

| Wavelength | 850nm |

| EFL | 1.5mm |

| FOV | 80 degrees |

| Spot size (FWHM) | Diffraction limited |

| Lens Diameter | 0.42mm |

| Transmission Efficiency | >90% |

| Mechanical Specifications | |

| Diameter | 0.42mm |

| Thickness | <1mm |

| Weight | <1gram |

| Spot Size (FWHM) | |

| 0 degrees | 7.3μm |

| 40 degrees | 10.7μm |

| 80 degrees | 22.4μm |

The performance of the large field-of-view TOF metalens is shown below as Point-spread Function

(PSF) at 850 nm. The PSF shows high performance focusing for the entire field of view 80 degrees.

Ordering number:

STOB-LFV-WW-XX-YY

WW : wavelength

XX : effective focal length (EFL)

YY : field of view (FOV)

Example:

STOB-LFV-1064-2-70

Wavelength = 1064nm

EFL = 2mm

FOV = 70 degree

4. STOB Series Metalens-Enabled Microlens Arrays for Imaging Applications

We have designed and built a freeform diffractive microlens array suitable for multiple applications in 3D integral imaging including:

Anti-counterfeiting technology

Physical security

3D displays

Lightfield cameras

Wavefront sensors

Fiber coupling

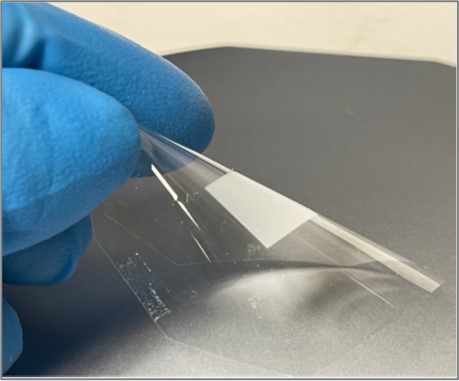

Metalens-enabled microlens array on a flexible substrate for imaging applications.

(Microlens pitch = 70μm, F-number: f/0.5, Substrate thickness 40μm)

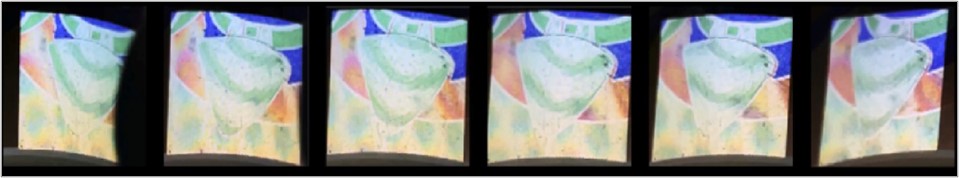

Integral imaging demonstrated using a metalens-enabled microlens array and a high-resolution color print. As the print plus the microlens array is tilted three dimensional patterns and colors change. This demonstration has applications in document security.

Major advantages of STOB Series Metalens technology:

Low f# (0.5 and larger)

Extended depth of focus for high robustness

Broadband performance in the visible, NIR, or LWIR

100% fill factor

Flexible device with ultra-low profile

Low-cost, large volume manufacturing with nano imprint lithography

Simplified alignment

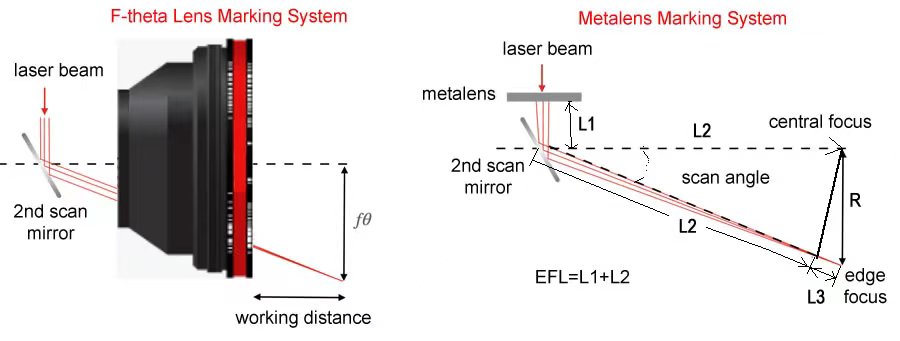

Metalenses are very suitable for laser processing, as they provide a long depth of focus and can easily and accurately mark and process various non planar objects.

Compared with traditional f-theta marking systems, the metalens marking system has the following advantages:

Ultra long depth of field (>75 mm), marking on non planar surfaces without the need for Z-axis movement, can also create consistent line width markings on non planar surfaces, especially suitable for 3D printing or non planar processing.

Due to the elimination of f-theta lens, the size of the scanning and marking head has decreased significantly.

Low cost, mass production.

Customizable metalenses for any laser wavelength.

Suitable for laser applications of all power levels, low-power laser applications can be used without coating.

Choosing a suitable metalens mainly considers laser wavelength, aperture (diameter of incident laser beam), effective focal length, depth of focus, diameter of focused spot, and laser power. At a laser power of around 50W, the metalens can operate stably without the need for coating. Choose the effective focal length based on the size of the marking area. The longer the focal length, the larger the marking area, but the larger the focusing spot. Therefore, it is necessary to choose a reasonable effective focal length.

Assuming that the distance from the metalens to the second scanning mirror is L1, the distance from the second scanning mirror to the working surface is L2, and the effective focal length of the metalens is EFL, then EFL=L1+L2. If the maximum scanning angle of the galvanometer is θ, The distance between the center focus and the edge focus is the radius R of the marking area, R=TAN(θ)* L2, R, the defocus amount at the outermost edge called as L3 is L3=L2/COSIN(θ)- L2, the defocus amount should be less than 1/2 of the depth of focus, and the marking will be as clear and uniform as the marking on the focal plane.

Assuming the side length of the square marking area and the maximum scanning optical angle of the galvanometer is ± 20 degrees, assuming L1=50mm, calculate the center wavelength and defocus amount of the metalens ± L3 as shown in the table below. When selecting the effective focal length EFL of the metalens, the distance from L1, which is the distance from the metalens to the second scanning mirror, also needs to be considered. That is, some focal lengths of the metalens EFL=L1+L2.

Marking area side length mm | Marking area radius R mm | Maximum scanning angle θ | L2 mm | Effective focal length EFL mm | Defocus L3 mm |

50x50 | 35.36 | 0.35 | 97.14 | 147.14 | 6.23 |

75x75 | 53.03 | 0.35 | 145.71 | 195.71 | 9.35 |

100x100 | 70.71 | 0.35 | 194.28 | 244.28 | 12.47 |

125x125 | 88.39 | 0.35 | 242.84 | 292.84 | 15.59 |

150x150 | 106.07 | 0.35 | 291.41 | 341.41 | 18.70 |

200x200 | 141.42 | 0.35 | 388.55 | 438.55 | 24.94 |

250x250 | 176.78 | 0.35 | 485.69 | 535.69 | 31.17 |

300x300 | 212.13 | 0.35 | 582.83 | 632.83 | 37.40 |

350x350 | 247.49 | 0.35 | 679.97 | 729.97 | 43.64 |

400x400 | 282.84 | 0.35 | 777.10 | 827.10 | 49.87 |

The following figure shows the marking effect at different distances between the marking surface and the metalens, with a defocus of up to 75mm, which can still be clearly marked.

The following table shows the range of some of our product parameters:

wavelength | Effective focal length EFL | Depth of focus (DOF) | diameter | Spot size |

355 nm | 25-100 mm | 25, 50 mm | 3-6 mm | 25-250 um |

532 nm | 25-100 mm | 25, 50 mm | 3-6 mm | 25-250 um |

1064 nm | 25-100 mm | 25, 50 mm | 3-6 mm | 25-250 um |

10.6 um | 25-100 mm | 25, 50 mm | 3-6 mm | 50-250 um |

A leading supplier and manufacturer of a wide range of photonics products such as lasers,laser parts & machines.

Office: 10 Bukit Batok Crescent #07-02 The Spire Singapore 658079

Tel: +65 63167112

Fax: +65 63167113

Whatsapp: +65 91904616