WhatsApp: +65 91904616 E-mail: sales@sintec.sg

WhatsApp: +65 91904616 E-mail: sales@sintec.sg

Blue laser has superior efficiency. Physics dictates the efficiency of energy absorption. Compared to industry-standard IR wavelength, blue absorption is maximum 66x better and blue laser enable process speed gains of 2-10x.

High brightness, fiber delivered blue lasers for metals processing

The STN Series Fiber Coupled Blue Lasers are high brightness blue lasers that process metals better and more efficiently than IR or green lasers and integrate with standard scanning systems. This enables them to service a wide range of welding, additive manufacturing, and other materials processing applications in batteries, e-mobility and consumer electronics. This series combined with scan head delivery, offers an ideal laser for metal processing due to the high absorption of blue light by metals: including 13x for copper and 3x for aluminum. Reducing the excess heat input compared to infrared lasers enables spatter-free and defect free welds with the highest possible mechanical and electrical performance. With available output powers from 125W to 1kW, these blue lasers can power mass production solutions for <1mm copper and aluminum welds which require a large process window and demand extremely high yields.

Key Benefits

High quality low to spatter-free welding

Dramatically improves process performance and process window

Enables welding processes not possible or with low yields with IR

Application

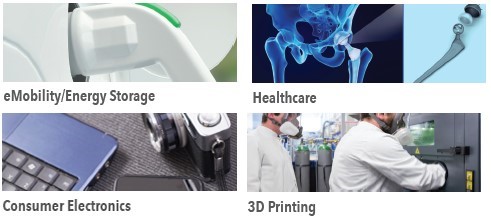

Batteries and energy storage

E-mobility

Consumer electronics

Interconnects

Electronics packaging

3D metal printing (powder bed fusion and wire feed)

| Optical | Units | STN-125-F | STN-250-F | STN-500-F | STN-1000-F |

| Wavelength | nm | ~444 | ~444 | ~444 | ~444 |

| Bandwidth | nm | ±15 | ±15 | ±15 | ±15 |

| Output Power | W | 125 | 250 | 500 | 1000 |

| Power Adjustment | % | 20-100 | 20-100 | 20-100 | 20-100 |

| Power Stability (8 hours) | % | ±1.5 at full power | |||

| Fiber Diameter (Core) | micron | 100 | 100 | 200 | 200 |

| Fiber Numerical Aperture | N/A | 0.22 | 0.22 | 0.22 | 0.22 |

| Beam Parameter Product (10-90% enclosed power) | mm.mrad | 5 | 5 | 15 | 15 |

| Standard Fiber Length (Connector Type) | m | 5 (QBH). Options for 10 and (QD) | |||

| Electrical | |||||

| Operating Current | A | <18 | <18 | <8 per phase | <8 per phase |

| Operating Voltage | V | 180/264 (47-63Hz) 1ph 3 wires | 208-240 (50/16Hz, 3ph 4 wires) | ||

| External Control Inputs Laser Enable (High on) CW Analog Control Modulation Communications | V V kHz | +5/+24 0-10 5 Ethernet | +5/+24 0-10 5 Ethernet | +5/+24 0-10 5 Ethernet | +5/+24 0-10 5 Ethernet |

| Safety Interlocks Interlock Voltage (Laser Enable) Open Circuit (Laser Shut-down) | V V | 24 0 | 24 0 | 24 0 | 24 0 |

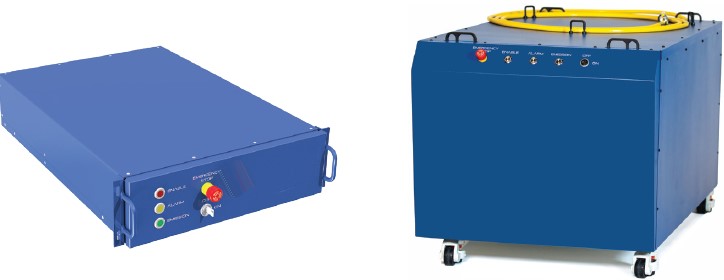

| Mechanical | Driver (19" Rack) | Driver (Stand Alone) | |||

| Height, Width, Depth | mm | 178 × 443 × 635 | 641 × 671 × 1183 | ||

| Weight | kg | 21 | 21 | ~160 | ~180 |

| IP Rating | IP20/NEMA 1 | IP52/NEMA 12 | |||

| Operating Conditions | |||||

| Temperature | Deg C | 15-25 | 15-25 | 15-25 | 15-25 |

| Relative Humidity (non-condensing) | % | 0-90 | 0-90 | 0-90 | 0-90 |

| Storage and Transport | |||||

| Temperature | Deg C | 0-40 | 0-40 | 0-40 | 0-40 |

| Cooling | |||||

| Heat Load | kW/Rton | 3/0.85 | 3/0.85 | 4/1.2 | 8/2.3 |

| Min Flow Rate | Lpm/gpm | 6/1.5 | 6/1.5 | 16.5/4.3 | 33/8.6 |

| Supply Temperature | Deg C | 15-25 | 15-25 | 20-24 | 20-24 |

| Max Pressure | bar/psi | 5.5/80 | 5.5/80 | 5.5/80 | 5.5/80 |

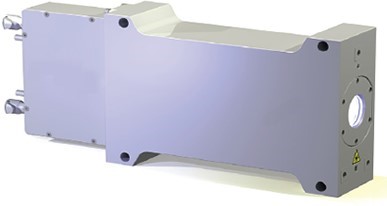

High brightness, free space output blue lasers for metals processing

The STN Series Free Space Blue Lasers are high brightness, blue lasers that process metals better and more efficiently than IR or green lasers and integrate with standard scanning systems. This enables them to service a wide range of welding, additive manufacturing, and other materials processing applications in batteries, e-mobility and consumer electronics. The high brightness of this series, combined with scan head delivery, offers an ideal laser for metal processing due to the high absorption of blue light by metals: including 13x for copper and 3x for aluminum. Reducing the excess heat input compared to infrared lasers enables spatter-free and defect free welds with the highest possible mechanical and electrical performance. With available output powers from 125W to 250W, these blue lasers can power mass production solutions for <500micron copper and aluminum welds which require a large process window and demand extremely high yields.

Key Benefits

Compact footprint to simplify integration

Capable of direct interface to standard scanners

All semiconductor laser reliability and lifetime

Lower cost of ownership than fiber and solid-state lasers

Spatter and defect free conduction mode welds

Higher weld joint densification

Application

Batteries for consumer electronics

Consumer electronics

Interconnects

Electronics packaging

Powder bed fusion 3D metal printing

| Optical | Units | STN-125 | STN-250 |

| Wavelength | nm | ~444 | ~444 |

| Bandwidth | nm | ±15 | ±15 |

| Output Power | W | 125 | 250 |

| Power Adjustment | % | 20-100 | 20-100 |

| Power Stability (8 hours) | % | ±1.5 at full power | |

| Collimator Aperture Diameter | micron | 20 or 30 | 20 or 30 |

| Beam Parameter Product (10-90% enclosed power) | mm.mrad | <5 | <5 |

| Electrical | |||

| Operating Current | A | <18 | <18 |

| Operating Voltage | V | 180/264 (47-63Hz) 1ph-3 wires | |

| External Control Inputs Laser Enable (High on) CW Analog Control Modulation Communications | V V kHz | +5/+24 0-10 5 Ethernet | +5/+24 0-10 5 Ethernet |

| Safety Interlocks Interlock Voltage (Laser Enable) Open Circuit (Laser Shut-down) | V V | 24 0 | 24 0 |

| Mechanical | Driver/Head with telescope | ||

| Height, Width, Depth | mm | H: 178/170 - W:443/100 - D: 635/410 | |

| Weight | kg | 21 | 11.4 |

| Power Supply | 19” Rack | ||

| IP Rating | IP20/NEMA 1 | ||

| Operating Conditions | |||

| Temperature | Deg C | 15-25 | 15-25 |

| Relative Humidity (non-condensing) | % | 0-90 | 0-90 |

| Storage and Transport | |||

| Temperature | Deg C | 0-40 | 0-40 |

| Cooling | |||

| Heat Load | kW/Rton | 3/0.85 | 3/0.85 |

| Min Flow Rate | Lpm/gpm | 6/1.5 | 6/1.5 |

| Supply Temperature | Deg C | 15-25 | 15-25 |

| Max Pressure | bar/psi | 5.5/80 | 5.5/80 |

Compared with traditional laser products, our blue diode laser has a higher absorption rate for materials such as copper and aluminium, and can process non-ferrous metals with lower power. Our blue laser is more compact and easier to use. With flexible laser output mode, it can be integrated into the processing system conveniently.

Our blue lasers can be used in wide applications like welding, cladding, surface treatment, lithium-ion battery manufacturing, etc. Our professional laser application team, with good knowledge and experience, provides the best laser system solution for our customers all around the world.

Features:

Good beam quality

High electro-optical conversion efficiency

Excellent power stability

Two operation modes: CW and modulation

Excellent system reliability

Max modulation frequency up to 5kHz

Easy-to-use control interface

Cost effective and maintenance free

Application:

Welding

Additive manufacturing

Surface treatment

Lithium-ion battery manufacturing

| Part number | STK-450-500-330 | STK-450-1000-400 | STK-450-1500-400 | STK-450-2000-600 |

| Power | 500W | 1000W | 1500W | 2000W |

| Wavelength | 450±5nm | 450±10nm | 450±5nm | 450±5nm |

| Output Fiber Core Diameter | 330μm | 330/400μm | 400μm | 600μm |

| Output Cable Length | 10m or Customized | 10m or Customized | 10m or Customized | 5m or Customized |

| Output Cable Connector | QBH | QBH or Customized | QBH | QBH |

| Aiming Beam | Red | Red | Red | Red |

| Operation Mode | CW or modulation | CW or modulation | CW or modulation | CW or modulation |

| Polarization | Random | Random | Random | Random |

| Power Stability (25>℃) | <±3% (2h) | <±3% (2h) | <±3% (2h) | <±3% (2h) |

| Power Adjustment Scope | 10%-100% | 10%-100% | 10%-100% | 10%-100% |

| Max Modulation Frequency | 5kHz | 5kHz | 5kHz | 5kHz |

| Physical Size (H×W×D) | 798×420×900mm | 798×420×900mm | 798×420×900mm | 800×750×1200mm |

| Weight | < 130 kg | < 80 kg | < 140 kg | < 140 kg |

| Power Supply | Three Phase, 380±20V, AC, PE, 50/60 Hz | Three Phase, 380±20V, AC, PE, 50/60 Hz | Three Phase, 380±20V, AC, PE, 50/60 Hz | Three Phase, 380±20V, AC, PE, 50/60 Hz |

| Power Consumption | 3.5kW | 5.0kW | 9.0kW | 10.0 kW |

| Control Interface | RS232/AD | RS232 | RS232/AD | RS232/AD |

| Minimum Water-Cooling Capacity | 3.0kW | 4.0kW | 8.0kW | 8.0 kW |

| Temperature Settings | 25>℃ (Laser Module), 30>℃ (QBH) | 25>℃ (Laser Module), 30>℃ (QBH) | 25>℃ (Laser Module), 30>℃ (QBH) | 25>℃ (Laser Module), 30>℃ (QBH) |

| Cooling Tubes Size | I.D. Φ25mm | I.D. Φ19mm | I.D. Φ25mm | I.D. Φ32mm |

| Cooling Water Flow Rate (Laser Module) | >20L/min | >25L/min | >25L/min | >50L/min |

| Cooling Water Flow Rate (QBH) | 1.5~2.0L/min | 2.0L/min | 2.0L/min | 1.5~2.0L/min |

Note: The back reflection will affect the performance and life of the direct diode laser. It is necessary to use the output laser when it is 8-10° away from the vertical direction of the surface.

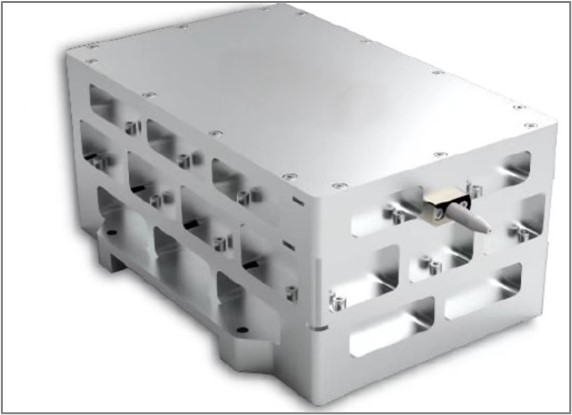

2.1 200W Blue Diode Lasers

Features:

445nm wavelength

100W/150W/200W output power

105μm fiber core diameter

0.22NA

Cooling mode: water cooling

Applications:

Material Processing

3D Printing

| Specification (20℃) | Symbol | STK- 445-200-105 | ||

| Minimum | Typical | Maximum | ||

| Optical Data (1) | ||||

| Total CW Output Power (W) | Pbol (4) | 200 | - | - |

| Number of submodules | pcs | - | 4 | - |

| Submodule CW Output Power (W) | Po | - | 50 | - |

| Center Wavelength (nm) | λc | 445±20 | 445±20 | 445±20 |

| Spectral Width (FWHM), (nm) | △λ | - | 6 | - |

| Wavelength Shift with Temperature, (nm/℃) | △ λ/△T | - | 0.1 | - |

| Wavelength Shift with Current, (nm/A) | △ λ/△A | - | 1 | - |

| Electrical Data | ||||

| Electrical-to-Optical Efficiency, % | PE | - | 30 | - |

| Operating Current, (A) | Ibol (4) | - | 3 | 3.5 |

| Threshold Current, (A) | Ith | - | 0.35 | - |

| Operating Voltage (single module), V | Vop | - | 52 | 60 |

| Slope Efficiency (single module), (W/A) | η | - | 18.5 | - |

| Power Supply Mode | - | - | 4 modules | - |

| Fiber Data | ||||

| Core Diameter, (μm) | Dcore | - | 105 | - |

| Numerical Aperture | NA | - | 0.22 | - |

| Minimum Bending Radius, (mm) | - | 50 | - | - |

| Fiber Length, (m) | - | 5.5 | ||

| Fiber Termination | - | - | HP-SMA905 | - |

| Thermistor, (KΩ)/β(25℃℃) | Rt | - | 10±3%/3450 | - |

| ESD (V) | Vesd | - | - | 500 |

| Storage Temperature (2), (℃) | Tst | -20 | 70 | |

| Lead Soldering Temp, (℃) | Tls | - | - | 260 |

| Lead Soldering Time, sec | t | - | - | 10 |

| Operating Temperature (3), (℃) | Top | 15 | - | 30 |

| Relative Humidity, % | RH | 15 | - | 75 |

Remark:

(1) Data measured under operation output at 200W@20℃℃.

(2) A non-condensing environment is required for operation and storage.

(3) Operating temperature defined by the thermistor. Acceptable operating range is 15℃℃~30℃℃, but performance may vary.

(4) Product delivery qualification standards: Ibeginning of life ≤ 3.5A Pbeginning of life ≥ 200W.

(5) Within the warranty period, the product is considered qualified with Iend of life =3.5A Pend of life 160W.

2.2. 150W Blue Diode Lasers

| Specification (20℃) | Symbol | STK- 445-150-105 | ||

| Minimum | Typical | Maximum | ||

| Optical Data (1) | ||||

| Total CW Output Power (W) | Pbol (4) | 150 | - | - |

| Number of submodules | pcs | - | 3 | - |

| Submodule CW Output Power (W) | Po | - | 50 | - |

| Center Wavelength (nm) | λc | 445±20 | 445±20 | 445±20 |

| Spectral Width (FWHM), (nm) | △λ | - | 6 | - |

| Wavelength Shift with Temperature, (nm/℃) | △ λ/△T | - | 0.1 | - |

| Wavelength Shift with Current, (nm/A) | △ λ/△A | - | 1 | - |

| Electrical Data | ||||

| Electrical-to-Optical Efficiency, % | PE | - | 30 | - |

| Operating Current, (A) | Ibol (4) | - | 3 | 3.5 |

| Threshold Current, (A) | Ith | - | 0.35 | - |

| Operating Voltage (single module), V | Vop | - | 52 | 60 |

| Slope Efficiency (single module), (W/A) | η | - | 18.5 | - |

| Power Supply Mode | - | - | 3 modules | - |

| Fiber Data | ||||

| Core Diameter, (μm) | Dcore | - | 105 | - |

| Numerical Aperture | NA | - | 0.22 | - |

| Minimum Bending Radius, (mm) | - | 50 | - | - |

| Fiber Length, (m) | - | 5.5 | ||

| Fiber Termination | - | - | HP-SMA905 | - |

| Thermistor, (KΩ)/β(25℃℃) | Rt | - | 10±3%/3450 | - |

| ESD (V) | Vesd | - | - | 500 |

| Storage Temperature (2), (℃) | Tst | -20 | 70 | |

| Lead Soldering Temp, (℃) | Tls | - | - | 260 |

| Lead Soldering Time, sec | t | - | - | 10 |

| Operating Temperature (3), (℃) | Top | 15 | - | 30 |

| Relative Humidity, % | RH | 15 | - | 75 |

Remark:

(1) Data measured under operation output at 150W@20℃.

(2) A non-condensing environment is required for operation and storage.

(3) Operating temperature defined by the thermistor. Acceptable operating range is 15℃℃~30℃℃, but performance may vary.

(4) Product delivery qualification standards: Ibeginning of life ≤ 3.5A Pbeginning of life ≥ 150W;

(5) Within the warranty period, the product is considered qualified with Iend of life =3.5A Pend of life 120W.

2.3 100W Blue Diode Lasers

| Specification (20℃) | Symbol | STK- 445-100-105 | ||

| Minimum | Typical | Maximum | ||

| Optical Data (1) | ||||

| Total CW Output Power (W) | Pbol (4) | 100 | - | - |

| Number of submodules | pcs | - | 2 | - |

| Submodule CW Output Power (W) | Po | - | 50 | - |

| Center Wavelength (nm) | λc | 445±20 | 445±20 | 445±20 |

| Spectral Width (FWHM), (nm) | △λ | - | 6 | - |

| Wavelength Shift with Temperature, (nm/℃) | △ λ/△T | - | 0.1 | - |

| Wavelength Shift with Current, (nm/A) | △ λ/△A | - | 1 | - |

| Electrical Data | ||||

| Electrical-to-Optical Efficiency, % | PE | - | 30 | - |

| Operating Current, (A) | Ibol (4) | - | 3 | 3.5 |

| Threshold Current, (A) | Ith | - | 0.35 | - |

| Operating Voltage (single module), V | Vop | - | 52 | 60 |

| Slope Efficiency (single module), (W/A) | η | - | 18.5 | - |

| Power Supply Mode | - | - | 2 modules | - |

| Fiber Data | ||||

| Core Diameter, (μm) | Dcore | - | 105 | - |

| Numerical Aperture | NA | - | 0.22 | - |

| Minimum Bending Radius, (mm) | - | 50 | - | - |

| Fiber Length, (m) | - | 5.5 | ||

| Fiber Termination | - | - | HP-SMA905 | - |

| Thermistor, (KΩ)/β(25℃℃) | Rt | - | 10±3%/3450 | - |

| ESD (V) | Vesd | - | - | 500 |

| Storage Temperature (2), (℃) | Tst | -20 | 70 | |

| Lead Soldering Temp, (℃) | Tls | - | - | 260 |

| Lead Soldering Time, sec | t | - | - | 10 |

| Operating Temperature (3), (℃) | Top | 15 | - | 30 |

| Relative Humidity, % | RH | 15 | - | 75 |

Remark:

(1) Data measured under operation output at 100W@20℃℃.

(2) A non-condensing environment is required for operation and storage.

(3) Operating temperature defined by the thermistor. Acceptable operating range is 15℃℃~30℃℃, but performance may vary.

(4) Product delivery qualification standards: Ibeginning of life ≤ 3.5A Pbeginning of life ≥ 100W;

(5) Within the warranty period, the product is considered qualified with Iend of life =3.5A Pend of life 80W.

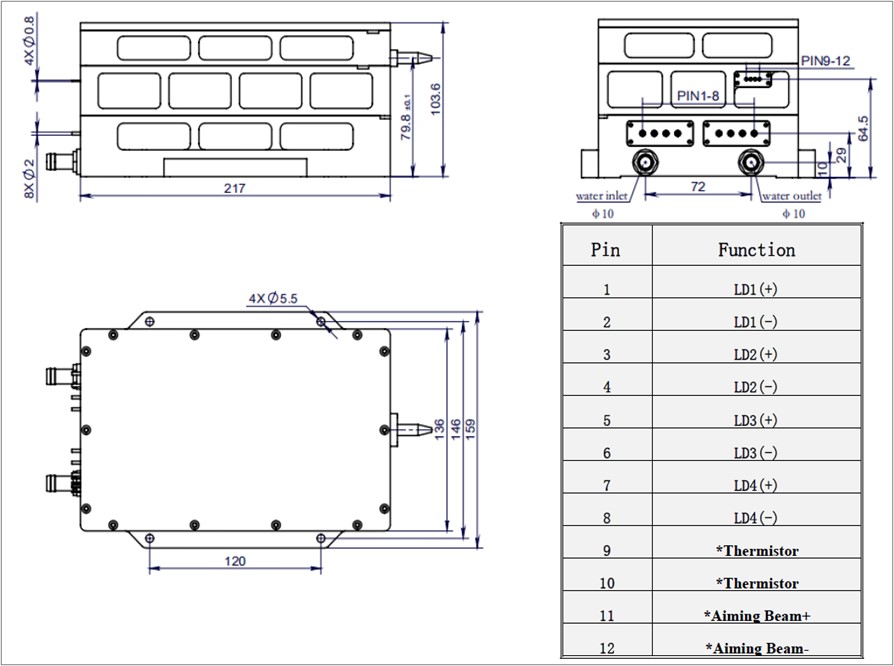

Packaging Dimension:

1. STK Series blue laser consists of up to 4 submodules(50W per module). Power can be supplied separately or in series.

2. STK Series blue laser cooling water inlet and outlet size: Outer 10mm* Inner 6.5mm.The water flow should be at least 5L/min.

3. *: Optional functions.

Operating Notes

Applications:

Avoid eye and skin exposure to direct radiation during operation.

ESD precautions must be taken during storage, transportation and operation.

Short circuit is required between pins during storage and transportation.

Please connect pins to wires by solder instead of using socket when operation current is higher than 6A. Soldering point should be close to the root of the pins. Soldering temperature should be lower than 260 and time shorter than 10 second.

Make sure the fiber output end is properly cleaned before operation of laser. Follow safety protocols to avoid injury when handling and cutting the fiber.

Use constant current power supply to avoid surge current during operation.

Laser diode must be used according to the specifications.

Laser diode must work with good cooling.

Operation temperature ranges from 15 to 30℃

Storage temperature ranges from -20 to +70℃

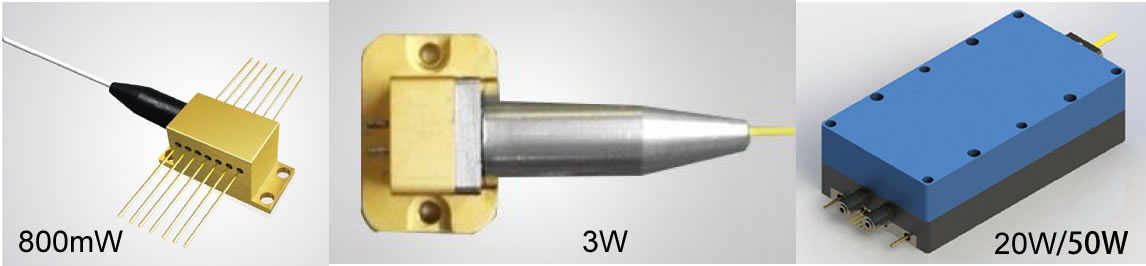

The STK series fiber-coupled blue lasers are manufactured by adopting specialized fiber-coupling techniques, resulting in high efficiency, stability and superior beam quality. The asymmetric radiation from the laser diode chips are coupled into an output fiber with small core diameter by using special micro optics. Their prices are reasonable and cheaper in the market.

| Part Number | STK450FFBFN-0.8W | STK445F03N-3W | STK445FTRFN-20W | STK445FTRFN-50W | |

| Optical Parameter | Laser power(W) | 0.8 | 3 | 20 | 50 |

| Wavelength(nm) | 450 | 445 | 445 | 445 | |

| Tolerance(nm) | ±10 | ±10 | ±10 | ±10 | |

| Spectral width(nm) | <6 | <6 | <6 | <6 | |

| Temperature drift (nm/K) | 0.3 | 0.1 | 0.1 | 0.1 | |

| Fiber Data | Core dia.(um) | 105 | 105 | 105 | 200 |

| NA | 0.22 | 0.22 | 0.22 | 0.22 | |

| Fiber Length (m) | 1.0 | 1.0 | 3.5 | 3.5 | |

| Connector | NIL | SMA905 | SMA905 | SMA905 | |

| Thermistor | K Ohm | option | 10 | 10 | |

| Electrical Parameter | Operation(A) | 1.0 | 3.0 | 2.5 | 2.8 |

| Threshold current(A) | 0.25 | 0.3 | 0.3 | 0.3 | |

| Operation voltage(V) | 4.8 | 5.2 | 41 | 81 | |

| Others | Operation temp.(oC) | 15-35 | 15-35 | 15-35 | 15-35 |

| Store temp.(oC) | -20-+70 | -20-+70 | -20-+70 | -20-+70 | |

| Dimension(mm) | 30x12.7x14.8 | 20x13.6x16 | 143x68x37 | 143x68x37 | |

| Pilot | option | ||||

A leading supplier and manufacturer of a wide range of photonics products such as lasers,laser parts & machines.

Office: 10 Bukit Batok Crescent #07-02 The Spire Singapore 658079

Tel: +65 63167112

Fax: +65 63167113

Whatsapp: +65 91904616