WhatsApp: +65 91904616 E-mail: sales@sintec.sg

WhatsApp: +65 91904616 E-mail: sales@sintec.sg

glass cutting, laser glass cutting machine, frigile material cutting, ps laser cutting, uv laser cutting, green laser cutting

P/N: SHR-LGPS-1064-60-10

Three axis laser glass cutting machine, using perfect score tecnology (PST) and particle swarm optimization (PSO) core technology to ensure high-speed cutting of shaped glass with chipping less than 10um. It has high database integration, accurate and fast to find out the best process parameters. Besides, it has PLC interactive system and easy to adapt to the integration of automated production lines.

Features:

Reduce cost and increase efficiency

Stable and reliable equipment

High speed cutting of shaped glass

Rapid integration of automated production lines

Laser subsystem in glass cutting:

Example of laser cutting system:

Product parameters:

Laser power | 60W/60kHz |

Laser wavelength | 1064nm |

Repetition rate | 50-300kHz |

Drawing file | Support software direct editing drawing, support CAD drawing file importing |

Pulse width | 10ps |

Maximum thickness of cutting | 6mm |

Spacing accuracy | +/-0.5um |

Machining resolution | 1um |

Amount of chipping | ≤10um |

Cutting speed | ≤300mm/s |

Processing width | 400mm×600mm(selectable) |

Processing acceleration | 1g |

Machining precision | <5um |

Vision module | expandable |

Platform type | Marble table |

Axis control | 4 control port |

Control interface | RS-232/ethernet |

Cable length | 3m |

Cooling method | Water cool |

Voltage | AC220V/AC110V, 50Hz/60Hz |

Storage temperature | 10°C ~ 35°C |

Operating temperature | 20°C ~ 30°C |

Humidity | <60% |

Environment dust | <0.20 mg/m3 |

Oil mist | Not allow |

Weight | ~70kg |

* The parameters can be customized upon request. Please contact us for more information.

Type of laser beam position:

Software:

PLC automatic programming

Programmable to interface with upstream and downstream stations on automated production lines

Graphic Editing features

Compatible with all types of editorial documents

Automatic optimization of machining paths

Customizable editing paths

Four axis control

Output four-axis control signals for rotary cutting

Layered processing function:

Automatic completion of 6 layer cutting

Fulfil 0.03-36mm glass cutting

Actual processing data is affected by the cutting head model

Control interface 4 in 1

Laser control software

Platform control software

Cutting software

Vision software

Sample display:

For more information on glass cutting processes, please refer to the video here. We can test to cut your samples free of charge at your requirements.

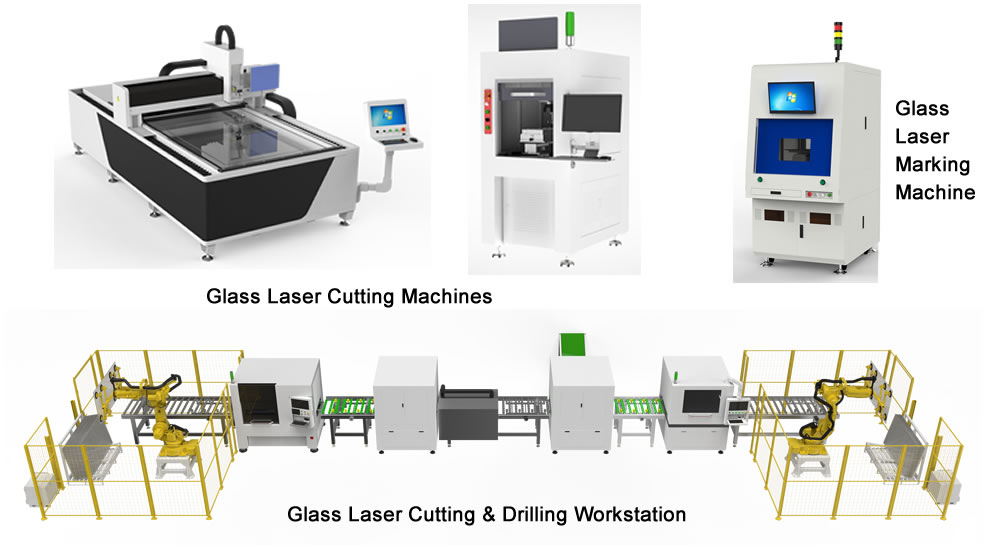

More glass laser processing machines available as follows. Please contact us if you have any special requirements.

A leading supplier and manufacturer of a wide range of photonics products such as lasers,laser parts & machines.

Office: 10 Bukit Batok Crescent #07-02 The Spire Singapore 658079

Tel: +65 63167112

Fax: +65 63167113

Whatsapp: +65 91904616