WhatsApp: +65 91904616 E-mail: sales@sintec.sg

WhatsApp: +65 91904616 E-mail: sales@sintec.sg

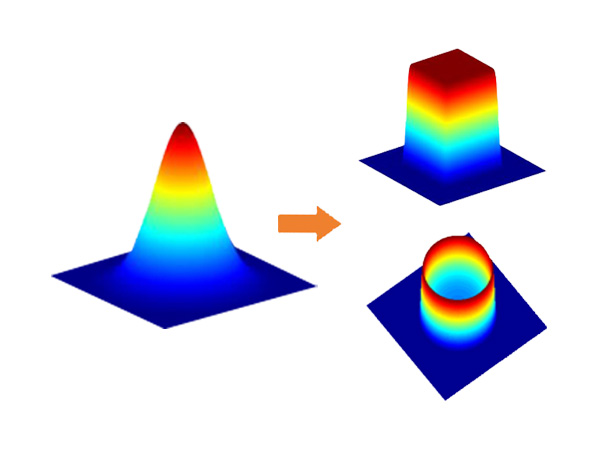

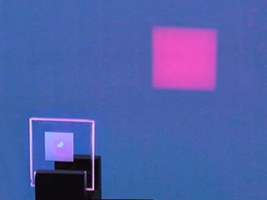

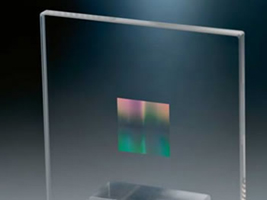

A Top-Hat beam shaper converts a Gaussian input laser beam into a uniform intensity beam of any shape and size requested by the customer. The beam shaping element is a diffractive optical element (DOE) used to transform a near-gaussian incident laser

A diffractive beam shaper allows you to modify the intensity and phase profiles of spatially coherent lasers. Through in-phase manipulation of the input beam, you can achieve virtually limitless and, most importantly, speckle-free intensity profiles in the output beam. This requires reliable and accurate knowledge of the input beam and phase profile.

You can optimize the performance and overall efficiency of your system, which could be in the application of laser material processing, in the field of lithography and holographic lighting as well as for biomedical devices and optical sensors.

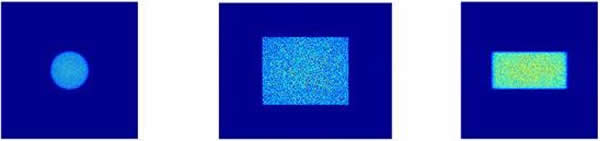

With our high-performance beam shapers, you can create uniform top-hat, circular rectangular, or linear intensity profiles as well as all manner of distributions and geometries – all according to your own specific requirements and applications. We design our beam shapers to be perfectly compatible with single-mode (TEM00) input beams. We also produce refractive or diffractive diffusers and homogenizers for use with multi-mode lasers to integrate the multi-mode beam. These cover a wavelength range from DUV to LWIR.

Single-mode lasers such as solid-state lasers, fiber lasers, diode lasers, gas lasers and frequency-doubled or -tripled lasers feature a Gaussian beam profile. These Gaussian profiles can´t be readily used for optimal for uniform lighting applications.

Diffractive line generators from Sintec use a single surface element without additional optics to convert a Gaussian laser beam into a uniform, one-dimensional top-hat profile. Uniform and speckle-free lines are ideal for material processing applications, such as annealing or recrystallization of semiconductors and thin layers. This type of illumination can be designed to create lines at normal incidence or even on highly tilted planes.

You use diffractive diffusers from Sintec to absorb a monochromatic laser beam and scatter the light into any imaginable pattern. Like the diffractive beam splitter, the diffuser converts an input beam into a multitude of output beams, the angle and intensity of which can be controlled.

However, in contrast with the beam splitter, these beams overlap and interfere, generating a new, homogenized distribution.

Diffractive diffusers are therefore ideal for laser applications, in which a specific laser beam shape is required, similarly to refractive homogenizers. They also allow you to realize uniform performance for a specific range at a defined distance from the light source. The optical elements achieve a uniformity of 3 to 5%, whereby the shape of the light distribution can be round, rectangular or freely selectable.

Our diffractive diffusers feature a strictly controlled beam angle, which guarantees you particularly high levels of efficiency. The diffusers are not alignment sensitive and have no impact on the polarization of the input beam. This makes the diffractive diffusers ideal for applications requiring rapid sensing of large areas, in the fields of remote sensing or LIDAR/LADAR, for example. The diffusers cover the wavelength range from DUV to infrared.

The diffractive Gaussian generators from Sintec represent a special type of diffractive diffuser and are ideally suited for high-power lasers such as excimer, nitrogen or diode lasers. They convert non-Gaussian laser beams into accurately defined, reproducible Gaussian far-field profiles.

The diffractive Gaussian generators from Sintec represent a special type of diffractive diffuser and are ideally suited for high-power lasers such as excimer, nitrogen or diode lasers. They convert non-Gaussian laser beams into accurately defined, reproducible Gaussian far-field profiles.

Such intensity profiles are ideal for overlapping laser beam processing – for example, during material processing and medical laser treatment or for printing technology and measuring systems. We can provide you with DOEs for wavelengths ranging from UV to NIR.

A Top-Hat beam shaper converts a Gaussian input laser beam into a uniform intensity beam of any shape and size requested by the customer.

The beam shaping element is a diffractive optical element (DOE) used to transform a near-gaussian incident laser beam into a uniform-intensity spot of either round, rectangular, square, line or other shape with sharp edges in a specific work plane.

A uniform spot enables equal treatment to a surface, excluding over/under-exposure of specific areas. In addition, the spot is characterized by a sharp transition region that creates a clear border between the treated and untreated area.

The beam shaping can be a:

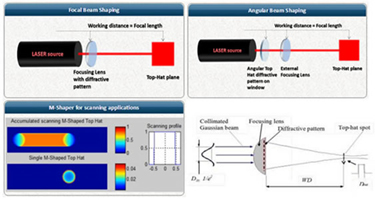

Focal Beam Shaping: Hybrid element (lens) or module which give a Top-Hat intensity distribution at a specific working distance (BFL of the lens or distance from exit location of the module to Top-Hat plane).

Angular Beam Shaping: Optical element (window) which gives a Top-Hat intensity distribution at infinity or focal length of aberration free customer's lens.

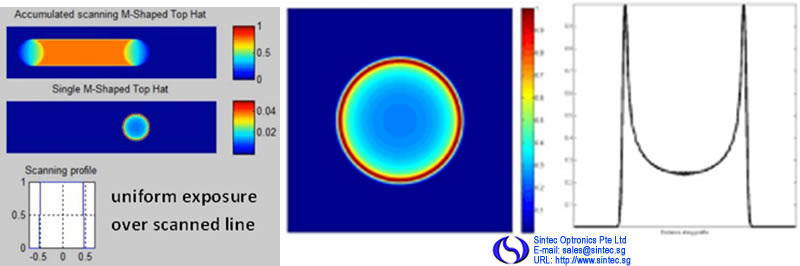

M-Shaper: Optical element (window) which gives a uniform exposure over scanned lines.

Focal Beam Shaper standard elements

| PN | Wavelength [nm] | Beam Dia [mm] | WD [mm] | Spot Size | Element Size [mm] | Image Shape |

| TH-042-U-Y-A | 355 | 2.5 | 50 | 50 um | 25.4 | Round |

| TH-245-U-Y-A | 355 | 12 | 50 | 45x10um | 25.4 | Rectangular |

| ST-202-U-Y-A | 355 | 14 | 50 | 50x6 um | 25.4 | Rectangular |

| ST-203-I-Y-A | 1064 | 6 | 52 | 50x50 um | 25.4 | Square |

| ST-204-Q-Y-A | 532 | 6 | 52 | 30 x 30 um | 25.4 | Square |

| TH-241-W-Y-A | 266 | 8 | 200 | 1mm | 25.4 | Line |

| TH-235-U-Y-A | 355 | 12 | 700 | 10mm | 27.94 | Line |

| ST-209-Q-Y-A | 532 | 2 | 104.76 | 150x200um | 12.7 | Rectangular |

| ST-211-A-Y-A | 10600 | 11 | 38 | 125x200um | 27.94 | Rectangular |

| ST-215-U-Y-A | 355 | 14 | 47.8 | 6x34um | 25.4 | Rectangular |

| ST-216-U-Y-A | 355 | 14 | 47.8 | 6x38um | 25.4 | Rectangular |

| ST-217-U-Y-A | 355 | 14 | 47.8 | 6x42um | 25.4 | Rectangular |

| TH-234-A-Y-A | 10600 | 14 | 95 | 250um | 27.94 | Round |

| TH-233-A-Y-A | 10600 | 12 | 63.5 | 0.25x2.5mm | 27.94 | Rectangular |

| TH-223-A-Y-A | 10600 | 2.4 | 565 | 27.8x27.8mm | 15 | Square |

| TH-222-Q-Y-A | 532 | 2.9 | 40 | 200um | 12.7 | Line |

| TH-219-A-Y-A | 10600 | 12 | 63.5 | 0.25x1.5mm | 27.94 | Rectangular |

| TH-217-U-Y-A | 355 | 2 | 100 | 100x100um | 12.7 | Square |

| TH-009-A-Y-A | 10600 | 10 | 63.5 | 280x280 um | 27.94 | Square |

| TH-011-A-Y-A | 10600 | 25 | 250 | 3 mm | 38.1 | Round |

| TH-216-Q-Y-A | 532 | 12 | 720 | 10x10mm | 25.4 | Square |

| TH-014-I-Y-A | 1064 | 7 | 42.52 | 190 um | 20 | Round |

| TH-017-I-Y-A | 1064 | 39 | 20000 | 635x5.3 mm | 50 | Rectangular |

| TH-018-I-Y-A | 1064 | 13 | 20000 | 635x635 mm | 38.1 | Square |

| TH-019-I-Y-A | 1064 | 3.5 | 100 | 210x210 um | 25.4 | Square |

| TH-209-U-Y-A | 355 | 9x6 | 200 | 100 um | 25.4 | Round |

| TH-208-A-Y-A | 10600 | 13 | 150 | 5 mm | 27.94 | Line |

| TH-034-Q-Y-A | 532 | 2.5 | 99.5 | 100x100 um | 25.4 | Square |

| TH-035-Q-Y-A | 532 | 2.5 | 99.5 | 90 um | 25.4 | Round |

| TH-036-Q-Y-A | 532 | 3.5 | 100 | 200x200 um | 25.4 | Square |

| ST-201-A-Y-A | 10600 | 16.5 | 187.5 | 360um | 38.1 | Round |

| TH-043-U-Y-A | 355 | 8 | 49.8 | 15 um | 20 | Round |

| TH-205-A-Y-A | 10600 | 4 | 100 | 1.5mm | 25.4 | Round |

| TH-045-U-Y-A | 355 | 1.65 | 94 | 170x170 um | 12.7 | Square |

| TH-046-U-Y-A | 355 | 2.5 | 95 | 61x61um | 12.7 | Square |

| TH-051-W-Y-A | 266 | 5 | 42 | 15 um | 25.4 | Round |

| TH-101-I-Y-A | 1064 | 3 | 100 | 150 um | 25.4 | Round |

| TH-102-I-Y-A | 1064 | 6 | 100 | 150 um | 25.4 | Round |

| TH-103-I-Y-A | 1064 | 9 | 1000 | 10x10 mm | 25.4 | Square |

| TH-202-A-Y-A | 10600 | 14.5 | 79.5 | 370um | 20 | Round |

| TH-203-D-Y-A | 2940 | 4 | 80 | 200 um | 11 | Round |

| TH-204-Q-Y-A | 532 | 3.5 | 105 | 200x200um | 25.4 | Square |

| ST-200-C-Y-A | 9250 | 12 | 63.5 | 260x260um | 27.94 | Square |

| TH-032-Q-Y-A | 532 | 10.9 | 200 | 2mm @FWHM | 25.4 | Round |

| TH-031-Q-Y-A | 532 | 5 | 52.4 | 100 um | 25.4 | Round |

| TH-005-C-Y-A | 9250 | 12 | 62.9 | 350 um | 27.94 | Round |

| TH-226-A-Y-A | 10600 | 4 | 100 | 3x3mm | 20 | Square |

| TH-231-I-Y-A | 1064 | 5 | 100 | 0.2x0.6mm | 12.7 | Rectangular |

| TH-004-A-Y-A | 10600 | 12 | 63.4 | 390 um | 27.94 | Round |

| TH-003-A-Y-A | 10600 | 3.7 | 41 | 650um | 12.7 | Line |

| TH-244-U-Y-A | 355 | 12 | 50 | 35x13um | 25.4 | Rectangular |

| TH-033-X-Y-A | 800 | 6 | 200 | 3 mm | 25.4 | Round |

| TH-012-H-Y-A | 1319 | 7 | 43.2 | 170 um | 20 | Round |

| TH-008-C-Y-A | 9250 | 10 | 62.9 | 260x260 um | 27.94 | Square |

| TH-232-X-Y-A | 1070 | 12 | 150 | 300x300um | 38.1 | Square |

| TH-007-C-Y-A | 9250 | 25 | 121 | 14.2X1.7 mm | 38.1 | Rectangular |

| TH-006-A-Y-A | 10600 | 25 | 125 | 15X1 mm | 38.1 | Rectangular |

| ST-208-X-Y-A | 1070 | 14 | 75 | 500x500um | 30 | Square |

| ST-205-I-Y-A | 1064 | 7 | 100 | 210x210um | 25.4 | Square |

| TH-044-1-Y-A | 337 | 8 | 49.4 | 20 um | 20 | Round |

| TH-224-X-Y-A | 1070 | 14 | 75.76 | 1x1mm | 38.1 | Square |

Angular Beam Shaper

| PN | λ [nm] | Beam Dia [mm] | θf [mRad] | Image size*** [um] for EFL=100mm | Element Size [mm] | Image Shape | Remarks |

| TH-238-I-Y-A | 1064 | 3 | 6 | 600 | 11 | Round | |

| ST-206-I-Y-A | 1064 | 10 | 2.7 | 270 | 25.4 | Line | |

| ST-219-I-Y-A | 1064 | 4 | 0.52 | 52 | 11 | Round | Binary TH |

| ST-225-I-Y-A | 1064 | 4.5 | 0.47 | 47 | 25.4 | Square | Binary TH |

| ST-234-I-Y-A | 1064 | 7 | 0.3 | 30 | 25.4 | Square | Binary TH |

| ST-237-I-Y-A | 1064 | 9 | 0.23 | 23 | 25.4 | Round | Binary TH |

| ST-241-I-Y-A | 1064 | 10 | 0.2 | 20 | 25.4 | Round | Binary TH |

| PT-001-I-N-A | 1064 | 6 | 0.56 | 56 | 30 | Square | |

| TH-258-I-Y-A | 1064 | 10 | 0.48 | 48 | 25.4 | Square | |

| ST-212-I-Y-A | 1064 | 7 | 1 | 100 | 20 | Square | |

| ST-277-I-Y-A | 1064 | 7 | 0.3 | 30 | 25.4 | Line | Binary TH |

| TH-227-I-Y-A | 1064 | 3 | 13.3 | 1330 | 11 | Round | |

| ST-283-I-Y-A | 1064 | 12 | 0.36x1.80 | 36.0x180.0 | 25.4 | Rectangular | |

| TH-215-I-Y-A | 1064 | 6 | 1 | 100 | 25.4 | Round | |

| ST-286-I-Y-A | 1064 | 12 | 0.35x2.70 | 35.0x270.0 | 25.4 | Rectangular | |

| TH-015-I-Y-A | 1064 | 5.1 | 14.5 | 1450 | 25.4 | Line | |

| TH-013-I-Y-A | 1064 | 7 | 17.5 | 1750 | 25.4 | Square | |

| ST-303-I-Y-A | 1064 | 7.5 | 0.28 | 28 | 25.4 | Round | Binary TH |

| ST-221-I-Y-A | 1064 | 4.7 | 0.44 | 44 | 25.4 | Round | Binary TH |

| ST-238-I-Y-A | 1064 | 10 | 0.2 | 20 | 25.4 | Square | Binary TH |

| ST-239-I-Y-A | 1064 | 6 | 0.35 | 35 | 25.4 | Round | Binary TH |

| ST-240-I-Y-A | 1064 | 8 | 0.26 | 26 | 25.4 | Round | Binary TH |

| ST-222-I-Y-A | 1064 | 5 | 0.41 | 41 | 25.4 | Round | Binary TH |

| PT-002-I-Y-A | 1064 | 7.5 | 45.18x2.64 | 4518.8x264.0 | 40x40 | Rectangular | |

| ST-259-I-Y-A | 1064 | 2 | 1.04 | 104 | 11 | Round | Binary TH |

| ST-260-I-Y-A | 1064 | 3 | 0.69 | 69 | 11 | Round | Binary TH |

| PT-001-I-Y-A | 1064 | 6 | 0.56 | 56 | 30 | Square | |

| ST-289-I-Y-A | 1064 | 3.5 | 0.6 | 60 | 11 | Round | Binary TH |

| TH-249-I-Y-A | 1064 | 3.2 | 0.74 | 74 | 12.5 | Line | Binary TH |

| TH-246-I-Y-A | 1064 | 6 | 4.2 | 420 | 25.4 | Round | |

| TH-239-I-Y-A | 1064 | 4.7 | 0.51 | 51 | 12.5 | Line | Binary TH |

| ST-227-I-Y-A | 1064 | 4 | 2 | 200 | 11 | Frame | Binary TH |

| ST-267-I-Y-A | 1064 | 2 | 1.04 | 104 | 11 | Line | Binary TH |

| ST-268-I-Y-A | 1064 | 3 | 0.69 | 69 | 11 | Line | Binary TH |

| ST-269-I-Y-A | 1064 | 4 | 0.52 | 52 | 11 | Line | Binary TH |

| ST-270-I-Y-A | 1064 | 5 | 0.43 | 43 | 11 | Line | Binary TH |

| ST-271-I-Y-A | 1064 | 2 | 1.3 | 130 | 11 | Round | Binary TH |

| ST-272-I-Y-A | 1064 | 3 | 0.87 | 87 | 11 | Round | Binary TH |

| ST-273-I-Y-A | 1064 | 5 | 0.52 | 52 | 25.4 | Round | Binary TH |

| ST-275-I-Y-A | 1064 | 8 | 0.26 | 26 | 25.4 | Line | Binary TH |

| ST-276-I-Y-A | 1064 | 10 | 0.21 | 21 | 25.4 | Line | Binary TH |

| ST-228-I-Y-A | 1064 | 4 | 24 | 2400.1 | 11 | Frame | Binary TH |

| ST-278-I-Y-A | 1064 | 9 | 0.23 | 23 | 25.4 | Line | Binary TH |

| ST-229-I-Y-A | 1064 | 4 | 12 | 1200 | 11 | Square | Binary TH |

| TH-221-I-Y-A | 1064 | 2.2 | 3.2 | 320 | 11 | Square | Binary TH |

| ST-281-I-Y-A | 1064 | 6 | 0.34 | 34 | 25.4 | Line | Binary TH |

| ST-282-I-Y-A | 1064 | 6 | 0.34 | 34 | 25.4 | Square | Binary TH |

| ST-230-I-Y-A | 1064 | 7 | 0.29 | 29 | 20 | Round | Binary TH |

| TH-220-I-Y-A | 1064 | 1.125 | 6.2 | 620 | 11 | Square | Binary TH |

| ST-231-I-Y-A | 1064 | 3 | 8.7 | 870 | 11 | Line | Binary TH |

| ST-232-I-Y-A | 1064 | 3 | 17.67 | 1767 | 11 | Line | Binary TH |

| ST-220-I-Y-A | 1064 | 4 | 0.53 | 53 | 11 | Square | Binary TH |

| ST-235-I-Y-A | 1064 | 8 | 0.26 | 26 | 25.4 | Square | Binary TH |

| ST-315-I-Y-A | 1064 | 1.5 | 1.39 | 139 | 11 | Square | Binary TH |

| ST-290-I-Y-A | 1064 | 3.5 | 0.6 | 60 | 11 | Square | Binary TH |

| ST-291-I-Y-A | 1064 | 2 | 1.02 | 102 | 11 | Square | Binary TH |

| ST-292-I-Y-A | 1064 | 2.5 | 0.81 | 81 | 11 | Square | Binary TH |

| ST-293-I-Y-A | 1064 | 3 | 0.68 | 68 | 11 | Square | Binary TH |

| ST-294-I-Y-A | 1064 | 2.5 | 0.83 | 83 | 11 | Line | Binary TH |

| ST-295-I-Y-A | 1064 | 3.5 | 0.59 | 59 | 11 | Line | Binary TH |

| ST-296-I-Y-A | 1064 | 4.5 | 0.46 | 46 | 11 | Line | Binary TH |

| ST-297-I-Y-A | 1064 | 2.5 | 0.84 | 84 | 11 | Round | Binary TH |

| ST-298-I-Y-A | 1064 | 4.5 | 0.47 | 47 | 11 | Round | Binary TH |

| ST-299-I-Y-A | 1064 | 5.7 | 0.4 | 40 | 11 | Round | Binary TH |

| ST-300-I-Y-A | 1064 | 5.7 | 0.49 | 49 | 11 | Round | Binary TH |

| ST-301-I-Y-A | 1064 | 5.7 | 0.37 | 37 | 12.5 | Round | Binary TH |

| ST-302-I-Y-A | 1064 | 5.7 | 0.48 | 48 | 12.5 | Round | Binary TH |

| ST-236-I-Y-A | 1064 | 9 | 0.23 | 23 | 25.4 | Square | Binary TH |

| ST-307-I-Y-A | 1064 | 1 | 2.08 | 208 | 11 | Round | Binary TH |

| ST-308-I-Y-A | 1064 | 1 | 2.08 | 208 | 11 | Square | Binary TH |

| ST-312-I-Y-A | 1064 | 1 | 2.08 | 208 | 11 | Line | Binary TH |

| ST-313-I-Y-A | 1064 | 1.5 | 1.39 | 139 | 11 | Line | Binary TH |

| ST-314-I-Y-A | 1064 | 1.5 | 1.39 | 139 | 11 | Round | Binary TH |

| ST-263-I-Y-A | 1064 | 12 | 0.36x2.39 | 36.0x239.0 | 25.4 | Rectangular | |

| ST-207-I-Y-A | 1064 | 10 | 0.6 | 60 | 25.4 | Round | |

| ST-288-I-Y-A | 1064 | 12 | 0.36x3.30 | 36.0x330.0 | 25.4 | Rectangular | |

| ST-287-I-Y-A | 1064 | 12 | 0.35x2.99 | 35.5x299.0 | 25.4 | Rectangular | |

| ST-285-I-Y-A | 1064 | 12 | 0.36x2.40 | 36.0x240.0 | 25.4 | Rectangular | |

| ST-284-I-Y-A | 1064 | 12 | 0.36x2.10 | 36.0x210.0 | 25.4 | Rectangular | |

| ST-280-I-Y-A | 1064 | 12 | 0.36x3.30 | 36.5x330.0 | 25.4 | Rectangular | |

| TH-225-I-Y-A | 1064 | 1.2 | 23.7 | 2370.1 | 11 | Dollar | |

| ST-279-I-Y-A | 1064 | 12 | 0.36x3.00 | 36.0x300.0 | 25.4 | Rectangular | |

| TH-228-I-Y-A | 1064 | 3 | 10 | 1000 | 11 | Round | |

| TH-236-I-Y-A | 1064 | 6 | 7.2 | 720 | 25.4 | Grid 10x10 cells | |

| TH-237-I-Y-A | 1064 | 6 | 7.2 | 720 | 25.4 | 11 lines | |

| ST-266-I-Y-A | 1064 | 12 | 0.37x2.40 | 36.9x239.5 | 25.4 | Rectangular | rounded corners |

| ST-265-I-Y-A | 1064 | 12 | 0.37x2.09 | 37.2x209.1 | 25.4 | Rectangular | rounded corners |

| ST-264-I-Y-A | 1064 | 12 | 0.36x2.69 | 36.5x269.0 | 25.4 | Rectangular | |

| TH-248-I-Y-A | 1064 | 5 | 5.60x0.94 | 560.0x94.0 | 25.4 | Rectangular | |

| TH-002-I-Y-A | 1064 | 12 | 2.4 | 240 | 27.94 | Square | |

| TH-252-I-Y-A | 1064 | 6 | 20 | 2000.1 | 25.4 | Round | |

| TH-253-I-Y-A | 1064 | 12 | 0.65x2.97 | 65.0x297.0 | 25.4 | Rectangular | |

| TH-254-I-Y-A | 1064 | 12 | 0.81x2.36 | 81.0x236.0 | 25.4 | Rectangular | |

| TH-255-I-Y-A | 1064 | 12 | 1.10x1.77 | 110.0x177.0 | 25.4 | Rectangular | |

| TH-256-I-Y-A | 1064 | 12 | 0.40x4.79 | 40.0x479.0 | 25.4 | Rectangular | |

| TH-257-I-Y-A | 1064 | 12 | 0.36x5.39 | 36.0x539.0 | 25.4 | Rectangular | |

| ST-262-I-Y-A | 1064 | 12 | 0.36x2.10 | 36.0x210.0 | 25.4 | Rectangular | |

| TH-259-I-Y-A | 1064 | 6 | 3.19 | 319 | 25.4 | Square | |

| TH-260-I-Y-A | 1064 | 6 | 1.71 | 171 | 25.4 | Square | |

| TH-105-I-Y-A | 1064 | 7.5 | 0.54 | 54 | 25.4 | Round | |

| TH-289-U-Y-A | 355 | 4 | 0.11 | 180x180 | 25.4 | Square | EFL=50mm |

| ST-261-I-Y-A | 1064 | 12 | 0.36x1.78 | 35.8x178.0 | 25.4 | Rectangular | |

| ST-258-I-Y-A | 1064 | 10 | 3.9 | 390 | 25.4 | Line | |

| ST-223-I-Y-A | 1064 | 6 | 3 | 300 | 25.4 | Line | |

| PT-003-I-Y-A | 1064 | 3.2 | 22.77 | 2277.1 | 12.7x12.7 | Line | |

| PT-005-I-Y-A | 1064 | 5 | 3.29 | 329 | 25.4 | Round | |

| PT-006-I-Y-A | 1064 | 2 | 40.30x57.10 | 4030.5x5711.6 | 12.7 | Elliptical | |

Small Angle Top Hat standard

Small Beam Shaper for scanning application (~1.5X Diffraction Limit)

Laser beams with Top-hat energy distribution are being used for different applications in the laser material processing industry. Most systems in this industry include scanners and F-θ lenses in order to direct and focus the beam on the substrate. HoloOr is proud to introduce a new design for ~1.5x(Diffraction limit) beam shapers DOEs (Diffractive Optical Element) which is considerably cheaper than regular Top-hats. Those DOEs are specially designed to operate with scanners/F-θ lenses under high power lasers. Placing the beam shaper DOE before the scanner will create a top-hat energy distribution at the F-θ lens working plane. The use of this beam shaper does not affect the focal length of the system.

A laser beam with a top-hat uniform intensity distribution is desired in many applications. A top-hat beam is also called a flat-top beam or a super-Gaussian beam. Basically we have 4 different methods to homogenize a laser beam, i.e.

The products were designed and fabricated based on our first method of homogenizing an incident laser beam. Product nomination for diffractive top-hat beam-shaping elements is as follows:

STO-TH-22-33-44-55-66-77

STO means STO series DOEs for flat-top beam shaping elements; TH means top hat; 22 means beam shape (RD means round, REC means rectangle); 33 means element size in mm; 44 means input beam diameter in mm; 55 means working distance in mm (INF means infinite via a lens); 66 means image size in mm or diffraction angle in degree or rad when working distance is infinite; 77 means wavelength. For example, STO-TH-RD-8-3.5-INF-1.4DEG-532.

Our standard top-hat beam shaping elements include Gaussian beam to rectangular flat-top beam and Gaussian beam to circular flat-top beam.

(1) Gaussian beam to rectangular flat-top beam

| Part No | DOE dimensions | Image size | Wavelength | Working distance |

| STO-TH-REC-8-2-INF-20mrad-1064 | 8 mm | 20 mrad | 1064 nm | Infinite |

| STO-TH-REC-8-2-200-4x4-1064 | 8 mm | 4x4 mm | 1064 nm | 200 mm |

| STO-TH-REC-8-2.5-INF-20mrad-1064 | 8 mm | 20 mrad | 1064 nm | Infinite |

| STO-TH-REC-8-2.5-200-4x4-1064 | 8 mm | 4x4 mm | 1064 nm | 200 mm |

| STO-TH-REC-8-3-INF-20mrad-1064 | 8 mm | 20 mrad | 1064 nm | Infinite |

| STO-TH-REC-8-3-200-4x4-1064 | 8 mm | 4x4 mm | 1064 nm | 200 mm |

| STO-TH-REC-8-3.5-INF-20mrad-1064 | 8 mm | 20 mrad | 1064 nm | Infinite |

| STO-TH-REC-8-3.5-200-4x4-1064 | 8 mm | 4x4 mm | 1064 nm | 200 mm |

| STO-TH-REC-10-4-INF-20mrad-1064 | 8 mm | 20 mrad | 1064 nm | Infinite |

| STO-TH-REC-10-4-200-4x4-1064 | 8 mm | 4x4 mm | 1064 nm | 200 mm |

| STO-TH-REC-20-8-INF-2.9 mrad-1064 | 20 mm | 2.9 mrad | 1064 nm | Infinite |

| STO-TH-REC-20-8-1700-5x5-1064 | 20 mm | 5x5 mm | 1064 nm | 1700 mm |

| STO-TH-REC-8-3.5-100-0.5x0.5-532 | 8 mm | 0.5x0.5 mm | 532 nm | 100 mm |

| STO-TH-REC-8-3-200-4x4-532 | 8 mm | 4x4 mm | 532 nm | 200 mm |

| STO-TH-REC-8-3.5-200-0.5x0.5-532 | 8 mm | 0.5x0.5 mm | 532 nm | 200 mm |

| STO-TH-REC-8-3.5-200-1x1-532 | 8 mm | 1x1 mm | 532 nm | 200 mm |

| STO-TH-REC-8-3.5-INF-5mrad-532 | 8 mm | 5 mrad | 532 nm | Infinite |

| STO-TH-REC-8-3.5-100-4.0x4.0-532 | 8 mm | 4.0x4.0 mm | 532 nm | 100 mm |

| STO-TH-REC-8-3.5-200-4.0x4.0-532 | 8 mm | 4.0x4.0 mm | 532 nm | 200 mm |

| STO-TH-REC-8-3.5-INF-40mrad-532 | 8 mm | 40 mrad | 532 nm | Infinite |

| STO-TH-REC-10-4.0--100-0.5x0.5-532 | 10 mm | 0.5x0.5 mm | 532 nm | 100 mm |

| STO-TH-REC-10-4.0-INF-5mrad-532 | 10 mm | 5 mrad | 532 nm | Infinite |

| STO-TH-REC-10-4.0-100-6.0x6.0-532 | 10 mm | 6.0x6.0 mm | 532 nm | 100 mm |

| STO-TH-REC-10-4.0--INF-59.9mrad-532 | 10 mm | 59.9 mrad | 532 nm | Infinite |

| STO-TH-REC-12-5.0-100-0.2x0.2-532 | 12 mm | 0.2x0.2 mm | 532 nm | 100 mm |

| STO-TH-REC-12-5.0--INF-20mrad-532 | 12 mm | 2 mrad | 532 nm | Infinite |

| STO-TH-REC-12-5.0-100-0.5x0.5-532 | 12 mm | 0.5x0.5 mm | 532 nm | 100 mm |

| STO-TH-REC-12-5.0-INF-5mrad-532 | 12 mm | 5 mrad | 532 nm | Infinite |

| STO-TH-REC-12-5.0-200-8.0x8.0-532 | 12 mm | 8.0x8.0 mm | 532 nm | 200 mm |

| STO-TH-REC-12-5.0-INF-40mrad-532 | 12 mm | 40.0 mrad | 532 nm | Infinite |

| STO-TH-REC-20-8.0-200-12x12-532 | 20 mm | 12x12 mm | 532 nm | 200 mm |

| STO-TH-REC-20-8.0-INF-99.7mrad-532 | 20 mm | 99.7 mrad | 532 nm | Infinite |

(2) Gaussian beam to circular flat-top beam:

| Part No | DOE dimensions | Image size | Wavelength | Working distance |

| STO-TH-RD-8-3.5-100-0.05-532 | 8 mm | 0.05 mm | 532 nm | 100 mm |

| STO-TH-RD-8-3.5-INF-0.5mrad-532 | 8 mm | 0.5 mrad | 532 nm | infinite |

| STO-TH-RD-8-3.5-100-0.1-532 | 8 mm | 0.1 mm | 532 nm | 100 mm |

| STO-TH-RD-8-3.5--INF-1mrad-532 | 8 mm | 1 mrad | 532 nm | infinite |

| STO-TH-RD-8-3.5-100-0.2-532 | 8 mm | 0.2 mm | 532 nm | 100 mm |

| STO-TH-RD-8-3.5-INF-2mrad-532 | 8 mm | 2 mrad | 532 nm | infinite |

| STO-TH-RD-8-3.5-100-0.5-532 | 8 mm | 0.5 mm | 532 nm | 100 mm |

| STO-TH-RD-8-3.5-INF-5mrad-532 | 8 mm | 5 mrad | 532 nm | infinite |

| STO-TH-RD-10-4.0-100-0.05-532 | 10 mm | 0.05 mm | 532 nm | 100 mm |

| STO-TH-RD-10-4.0-INF-0.5mrad-532 | 10 mm | 0.5 mrad | 532 nm | infinite |

| STO-TH-RD-10-4.0-100-0.1-532 | 10 mm | 0.1 mm | 532 nm | 100 mm |

| STO-TH-RD-10-4.0-INF-1mrad-532 | 10 mm | 1 mrad | 532 nm | infinite |

| STO-TH-RD-10-4.0-100-0.2-532 | 10 mm | 0.2 mm | 532 nm | 100 mm |

| STO-TH-RD-10-4.0-INF-2mrad-532 | 10 mm | 2 mrad | 532 nm | infinite |

| STO-TH-RD-10-4.0-100-0.5-532 | 10 mm | 0.5 mm | 532 nm | 100 mm |

| STO-TH-RD-10-4.0-INF-5mrad-532 | 10 mm | 5 mrad | 532 nm | infinite |

| STO-TH-RD-12-5.0-100-0.05-532 | 12 mm | 0.05 mm | 532 nm | 100 mm |

| STO-TH-RD-12-5.0-INF-0.5mrad-532 | 12 mm | 0.5 mrad | 532 nm | infinite |

| STO-TH-RD-12-5.0-100-0.1-532 | 12 mm | 0.1 mm | 532 nm | 100 mm |

| STO-TH-RD-12-5.0-INF-1mrad-532 | 12 mm | 1 mrad | 532 nm | infinite |

| STO-TH-RD-12-5.0-100-0.2-532 | 12 mm | 0.2 mm | 532 nm | 100 mm |

| STO-TH-RD-12-5.0-INF-2mrad-532 | 12 mm | 2 mrad | 532 nm | infinite |

| STO-TH-RD-12-5.0-100-0.5-532 | 12 mm | 0.5 mm | 532 nm | 100 mm |

| STO-TH-RD-12-5.0-INF-5mrad-532 | 12 mm | 5 mrad | 532 nm | infinite |

| Part Number | DOE receiving size | Wavelength | Diffraction angle | Description |

| STO-SFH-RD-12p5-25DEG-785 | 12.5x12.5mm | 785nm | 25degree | |

| STO-SFH-RD-12.5-25DEG-785-S | 12.5x12.5mm | 785nm | 25degree | Collimation of incident laser beam is not required |

| STO-SFH-REC-10-83p25x83p25mrad-532 | 10x10mm | 532nm | 83.25x83.25 mrad |

Equivalent to 0.333x0.333mm @4mm working distance |

| STO-SFH-REC-50-4p3x11mrad-1064 | Φ50mm | 1064nm | 4.3x11mrad | Equivalent to 1.3x3.3mm @ 300mm working distance |

| STO-SFH-REC-50-2x5p3mrad-1064 | Φ50mm | 1064nm | 2x5.3mrad | Equivalent to 0.6x1.6mm @ 300 mm working distance |

| STO-SFH-REC-50-20x20mrad-1064 | Φ50mm | 1064nm | 20x20mrad | Equivalent to 6x6mm @ 300 mm working distance |

| STO-SFH-REC-25-10mrad-1064 | Φ25mm | 1064nm | 10mrad | Equivalent to 3x3mm @ 300 mm working distance |

| STO-SFH-RD-50-20mrad-1064 | Φ50mm | 1064nm | 20mrad | Equivalent to 6 mm in diameter round output spot @ 300 mm working distance |

| STO-SFH-REC-30-p5xp5mrad-1064 | 30 x 30mm | 1064nm | 0.5x0.5mrad | Equivalent to a 30x30micron output spot @60mm working distance |

| STO-SFH-REC-12-p15xp45mrad-355 | 12 x 12mm | 355nm | 0.15x0.4mrad | Equivalent to a 20x60micron output spot @134mm working distance |

| STO-SFH-REC-25-p15xp45mrad-355 | 25 x 25mm | 355nm | 0.15x0.45

mrad |

Equivalent to a 20x60 micron output spot @134mm working distance |

| STO-SFH-REC-18-4mrad-355 | 18 x 18mm | 355nm | 4x4 mrad | |

| STO-SFH-REC-18-5p2mrad-355 | 18 x 18mm | 355nm | 5.2x5.2mrad | |

| STO-SFH-REC-12-p45x1p35mrad-1064 | 12 x 12mm | 1064nm | 0.45x1.35mrad |

The products were designed and fabricated based on our third method of homogenizing an incident laser beam. One main advantage of this type of product is its insensitivity to the incident beam quality and the change of intensity. Hence it is most suitable for the less stable lasers, laser with long pulse duration or multi-pulse laser applications. Due to the lengthy exposure time, the intensity fluctuation can be averaged to some extent. For a circularly symmetric output beam, the variation in intensity can be further impressed by rotating the beam homogenizer.

| Item No | DOE receiving size | Wavelength | Diffraction angle |

| STO-DF-RD-6-2-473 | 6 x 6 mm | 473 nm | 2 deg |

| STO-DF-RD-6-3-589 | 6 x 6 mm | 589 nm | 3 deg |

| STO-DF-RD-6-4-785 | 6 x 6 mm | 785 nm | 4 deg |

| STO-DF-RD-6-4-808 | 6 x 6 mm | 808 nm | 4 deg |

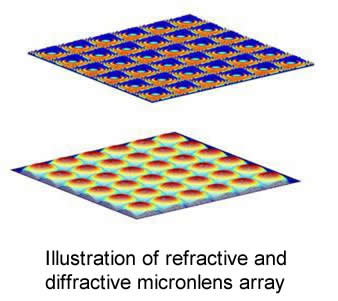

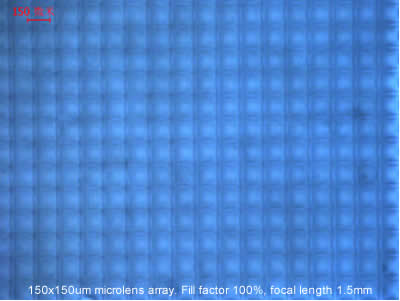

We have developed a variety of microlens arrays. The diameter or side length of each individual microlens can be as small as 2 micron. Since 2014, we have managed to increase the upper limit of the diameter or side length of each individual microlens from around 400 micron to 2,000 micron, and managed to increase the lens sag height from around 15 micron to 70 micron. Correspondingly the focal length of the microlens array can be from a few micron to 20,000 micron at visible wavelengths. The shape of the microlens array can be circular, square or hexagon. Specifications outside the ranges stated here are also possible upon customers‘ request.

AFM picture of 14 micron microlens array. The non-symmetry is caused by the measurement error of AFM, which is ideal to measure the height differences but may have error during the measurement of continuous profiles.

| Part Number | Shape | Pitch (um) | Number of microlens | Dimension | ROC(um) | focal length (um) | ROC error |

| STO-MLA-R14 | Round | Φ14 | 7~15 | 12~36 | <+/-5% | ||

| STO-MLA-S14 | Square | 14x14 | 7~15 | 12~36 | <+/-5% | ||

| STO-MLA-S25 | Square | 25x25 | 248x184 | 6.2x4.6 | ~17 | ~37 | <+/-5% |

| STO-MLA-S80 | Square | 80x80 | 625x625 | 50x50 | ~58 | ~120 | <+/-5% |

| STO-MLA-S96 | Square | 96x96 | 105x210 | 10x20 | 1440 | ~ 3000 | <+/-5% |

| STO-MLA-S120 | Square | 120x120 | 83x126 | 10x20 | 2250 | ~ 5000 | <+/-5% |

| STO-MLA-R150 | Round | Φ150 | 32x32 | 4.8x4.8 | 200~690 | 450~1500 | <+/-5% |

| STO-MLA-S150 | Square | 150x150 | 32x32 | 4.8x4.8 | 200~690 | 450~1500 | <+/-5% |

| STO-MLA-S150-170 | Square | 150x150 | 148x148 | 22.2x22.2 | 138~170 | 138~170 | <+/-5% |

| STO-MLA-R250 | Round | Φ250 | 24x24 | 6x6 | 547 | ~1000 | <+/-5% |

| STO-MLA-S250 | Square | 250x250 | 24x24 | 6x6 | 547 | ~1000 | <+/-5% |

| STO-MLA-H50-43.3 | Hexagon | 50x43.3 | 28.33 (height15 micron) |

~62 | <+/-5% | ||

| STO-MLA-R825-f13000 | Round | 825 | 17 x17 | 14 x14 | 13000 | <+/-5% |

M-Shaper, is a diffractive optical elements (DOE) used to create a unique 2D M-shaped intensity profile, with sharp edges in a specific work plane. The M-Shaper optical function is not possible by conventional reflective or refractive optical elements. The typical application is to create a uniform exposure over scanned lines. That is, when scanning a line with a regular Gaussian or even Top-Hat spot the center gets over exposed (influencing the heat distribution during laser material processing). The M-Shape is the mathematical shape that gives a uniform exposure over the line when scanned. This provides higher quality of the process & enables more flexibility in the system configuration. For example, it allows optimization of the intensity profile, and image size, without changing the laser, fiber cable and/or scanning optical head.

The benefits of our optimized M-shaped intensity profile include:

The most M-Shape DOE’s listed below require a Single Mode (TEM00) input beam. However, some M-Shape DOE’s had been designed for Multimode lasers (with MM in remarks column). Please feel free to contact us on this or any other custom request you may have.

| PN | λ[nm] | Beam Diameter (mm) | Image Shape | θf [deg] | Image size*** [mm] for EFL=100mm |

| MR-003-I-Y-A | 1064 | 5.3 | Round | 0.43 | 43 |

| MR-004-I-Y-A | 1064 | 5.7 | Round | 0.4 | 40 |

| MR-006-I-Y-A | 1064 | 10.2 | Round | 0.23 | 23 |

| MR-009-I-Y-A | 1064 | 11.3 | Round | 0.21 | 21 |

| MR-010-I-Y-A | 1064 | 2.3 | Round | 1.02 | 102 |

| MR-013-I-Y-A | 1064 | 4.2 | Round | 13.32 | 1332 |

| MR-015-I-Y-A | 1064 | 4.2 | Round | 6.06 | 606 |

| MR-002-I-Y-A | 1064 | 4.5 | Round | 0.52 | 52 |

| MR-005-I-Y-A | 1064 | 7.9 | Round | 0.29 | 29 |

| MR-007-I-Y-A | 1064 | 6.8 | Round | 0.34 | 34 |

| MR-008-I-Y-A | 1064 | 9 | Round | 0.26 | 26 |

| MR-011-I-Y-A | 1064 | 3.4 | Round | 0.69 | 69 |

| MR-001-I-Y-A | 1064 | 8.5 | Round | 4.26 | 426 |

| MR-012-I-Y-A | 1064 | 8.4 | Round | 1.03 | 103 |

| MR-014-I-Y-A | 1064 | 4.2 | Round | 10.13 | 1013 |

| MR-017-I-Y-A | 1064 | 8.4 | Round | 0.47 | 47 |

| MR-018-I-Y-A | 1064 | 6 | Round | 3.21 | 321 |

| RD-232-I-Y-A | 1064 | >1.5 | Round | 34.9 | 3490.4 |

| RD-247-I-Y-A | 1064 | >6 | Round | 8.73 | 873 |

| RD-254-I-Y-A | 1064 | >4 | Round | 17.45 | 1745 |

| MR-016-I-Y-A | 1064 | 7 | Round | 3.32 | 332 |

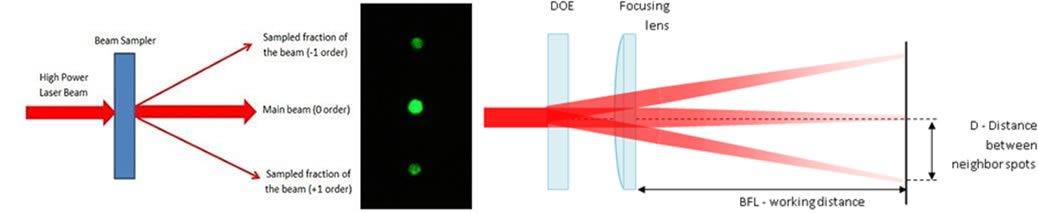

Diffractive beam samplers are used to monitor high power lasers where optical losses and wavefront distortions of the transmitted beam need to be kept to a minimum. In most applications, most of the incident light must to continue forward, "unaffected," in the "zero order" while a small amount of the beam is diffracted into a higher order, providing a "sample" of the beam. By directing the sampled light in the higher order(s) onto a detector, it is possible to monitor, in real time, not only the power levels of a laser beam, but also its profile. A Laser Beam Sampler allows the high power beam (zero order) to propagate undisturbed along the optical axis, but produces two side beams with low energy. These two sample beams are located to the left and right of the main beam (-1 and +1 orders), and are characterized by a given separation angle between them and by a sample power ratio. It is relatively easy to modify the sampling ratio upon a request of the customer.

| PN | λ[nm] | Sampled Energy [%] | Sampled Angle [deg] | Element Size [mm] |

| SA-010-I-Y-A | 1064 | 0.4 | 15.43 | 12x12 |

| SA-014-I-Y-A | 1064 | 0.4 | 15.43 | 25.4 |

| SA-022-I-Y-A | 1064 | 1.22 | 2.07 | 25.4 |

| SA-220-I-Y-A | 1064 | 0.5 | 10.21 | 11 |

| SA-020-I-Y-A | 1064 | 1 | 1.27 | 27.94 |

| SA-021-I-Y-A | 1064 | 1 | 1 | 25.4 |

| SA-219-I-Y-A | 1064 | 0.5 | 2.44 | 25.4 |

| SA-204-I-Y-A | 1064 | 0.5 | 2.07 | 25.4 |

| SA-206-I-Y-A | 1064 | 1 | 2.07 | 25.4 |

| SA-207-I-Y-A | 1064 | 2 | 10 | 15 |

| SA-218-I-Y-A | 1064 | 0.5 | 1 | 25.4 |

| SA-217-I-Y-A | 1064 | 0.5 | 2.84 | 25.4 |

| SA-216-I-Y-A | 1064 | 0.5 | 3.81 | 25.4 |

| SA-213-I-Y-A | 1064 | 0.5 | 9.21 | 15 |

| SA-215-I-Y-A | 1064 | 0.5 | 5.09 | 25.4 |

| SA-208-I-Y-A | 1064 | 2 | 5.09 | 15 |

| SA-211-I-Y-A | 1064 | 1 | 20.77 | 10x10 |

| SA-209-I-Y-A | 1064 | 3.8 | 15.43 | 10.7x10.7 |

| SA-011-I-Y-A | 1064 | 1.6 | 15.43 | 12x12 |

| SA-012-I-Y-A | 1064 | 3.8 | 15.43 | 12x12 |

| SA-214-I-Y-A | 1064 | 0.5 | 7.64 | 9.8x9.8 |

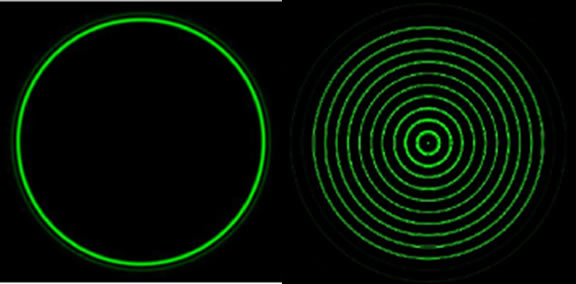

A Ring generator transforms a laser beam into a ring (Diffractive axicon) or into a multi-rings (Multi-Circles).

A laser concentric circles pattern transforms a laser beam into multiple circles.

A concentric circles light pattern can be used for certain 3D mapping applications, especially within pipe/tube objects.

A concentric circles pattern was recently proved to be the most appropriate light pattern for certain 3D mapping applications, especially with pipe/tube objects.

Each laser concentric circles is defined by its full angle and its number of rings.

We offer, in addition to its standard products, the possibility to design and manufacture a number of circles, separation angle between the circles and full angle as requested by the customer, as a part of its custom design and manufacturing capability.

We also design and manufacture diffractive axicon which is a DOE that splits an input beam to a single ring.

An Axicon transforms a laser beam into a ring shape (a Bessel intensity profile).

The ring's thickness will be equivalent to the diffraction-limited-spot size (of the input laser beam).

An Axicon also images a point source into a line along the optical axis and increases the Depth Of Focus (DOF). Each diffractive Axicon product is defined by its ring propagation angle.

Axicon for single ring shape

| PN | λ[nm] | Element Size [mm] | Ring Angle [deg] P2P(+) | Ring Dia(+) [mm] for EFL=100mm | Remarks |

| DA-004-I-Y-A | 1064 | 25.4 | 8.14 | 14.231 | |

| DA-011-I-Y-A | 1064 | 25.4 | 0.061 | 0.106 | |

| DA-003-I-Y-A | 1064 | 25.4 | 0.3 | 0.524 | |

| DA-017-I-Y-A** | 1064 | 34 | 1.52 | 2.653 | |

| DA-006-I-Y-A | 1064 | 11 | 0.24 | 0.419 | |

| DA-032-I-Y-A | 1064 | 25.4 | 3.6 | 6.285 | |

| DA-008-I-Y-A | 1064 | 11 | 0.49 | 0.855 | |

| DA-009-I-Y-A | 1064 | 11 | 0.98 | 1.71 | |

| DA-010-I-Y-A | 1064 | 25.4 | 0.081 | 0.141 | |

| DA-033-I-Y-A | 1064 | 25.4 | 7.2 | 12.583 | |

| DA-012-I-Y-A | 1064 | 11 | 2 | 3.491 | |

| DA-031-I-Y-A | 1064 | 25.4 | 1.8 | 3.142 | |

| DA-014-I-Y-A** | 1064 | 34 | 0.19 | 0.332 | |

| DA-015-I-Y-A** | 1064 | 34 | 0.38 | 0.663 | |

| DA-016-I-Y-A** | 1064 | 34 | 0.76 | 1.326 | |

| DA-005-I-Y-A | 1064 | 11 | 0.12 | 0.209 | |

| DA-018-I-Y-A | 1064 | 11 | 1.72 | 3.002 | |

| DA-019-I-Y-A | 1064 | 11 | 2.29 | 3.997 | |

| DA-020-I-Y-A | 1064 | 11 | 0.057 | 0.099 | |

| DA-021-I-Y-A | 1064 | 11 | 0.086 | 0.15 | |

| DA-029-I-Y-A | 1064 | 11 | 1.39 | 2.426 | |

| DA-028-I-Y-A | 1064 | 11 | 0.7 | 1.222 | |

| DA-027-I-Y-A | 1064 | 11 | 0.35 | 0.611 | |

| DA-026-I-Y-A | 1064 | 11 | 0.17 | 0.297 | |

| DA-025-I-Y-A | 1064 | 11 | 0.35 | 0.611 | High Efficiency |

| DA-024-I-Y-A | 1064 | 11 | 0.17 | 0.297 | High Efficiency |

| DA-023-I-Y-A | 1064 | 11 | 0.24 | 0.419 | High Efficiency |

| DA-013-I-Y-A | 1064 | 34 | 0.19 | 0.332 | High Efficiency |

| DA-007-I-Y-A | 1064 | 11 | 0.12 | 0.209 | High Efficiency |

| DA-002-I-Y-A | 1064 | 7.25x7.25 | 30.85 | 55.183 |

Concentric Circles Pattern

| Part Number | λ (nm) | number of rings | Full Angle (Deg) | Dimensions(mm) | Material | Coating |

| MC-006-I-Y-A | 1064 | 2 | 1.83 | 11 | Fused Silica | AR V-Coating |

| MC-005-I-Y-A | 1064 | 2 | 3.66 | 11 | Fused Silica | AR V-Coating |

| MC-017-1-Y-A | 808 | 12 | 5.9 | 11 | Fused Silica | AR V-Coating |

A leading supplier and manufacturer of a wide range of photonics products such as lasers,laser parts & machines.

Office: 10 Bukit Batok Crescent #07-02 The Spire Singapore 658079

Tel: +65 63167112

Fax: +65 63167113

Whatsapp: +65 91904616